Three tools, one goal: perfect fillet weld seams

Find your fillet weld specialist

Fillet weld grinding improves the quality of your welded joints and enhances corrosion resistance, while minimising the need for finishing work.

It also extends the service life of components and optimises the stress absorption for greater safety and reliability.

Be inspired by the leading-edge possibilities of grinding!

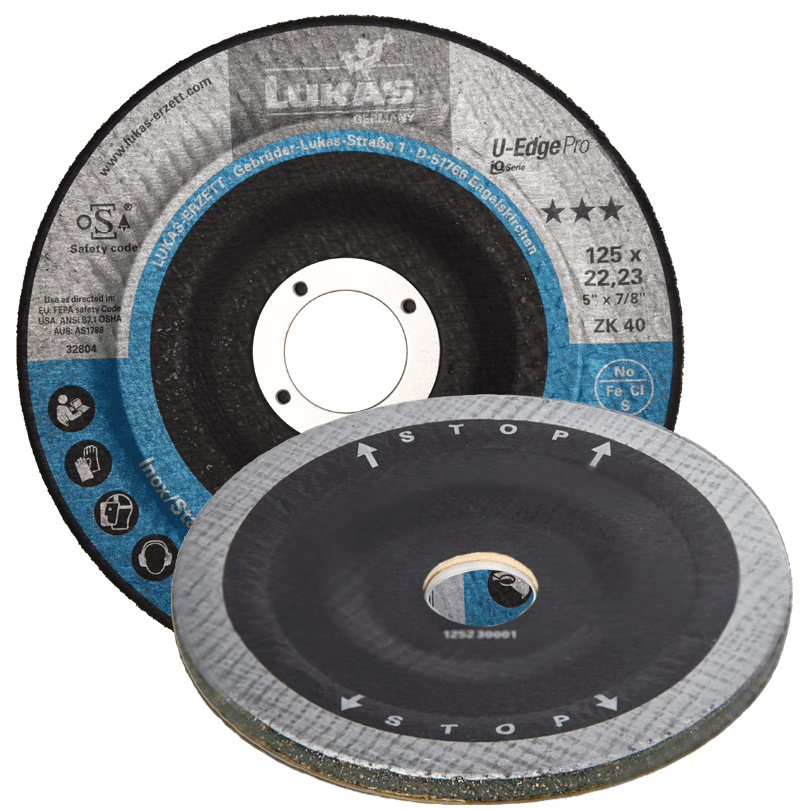

U-Edge Pro

The radial abrasive surface on the disc makes the U-Edge Pro extremely versatile.

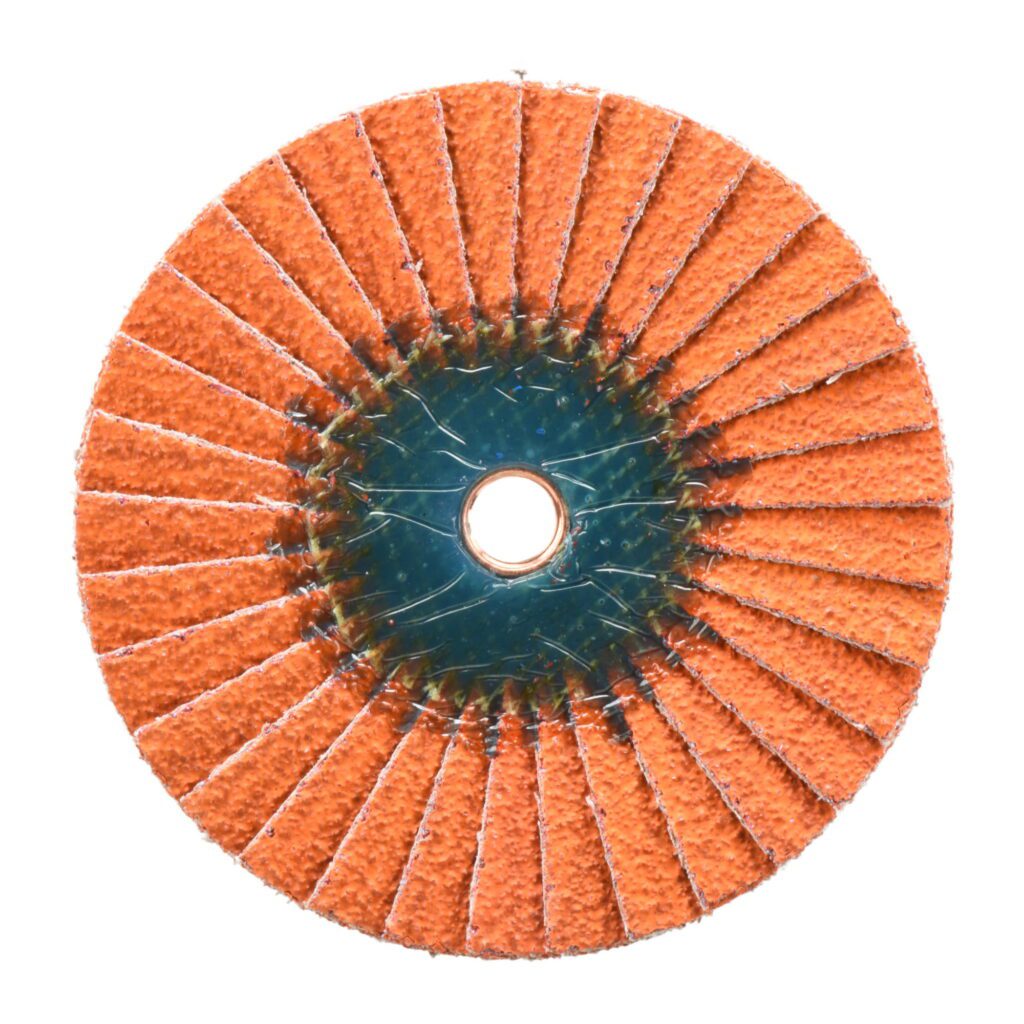

V2 Edge CeramicAd

Maximum performance and precision for demanding grinding work.

SLT flex CeramicAd

Flexible and powerful for hard-to-reach areas.

Innovative grinding of fillet weld seams

U-Edge Pro

The U-Edge Pro impresses with its effective and precise machining of fillet weld seams and offers maximum tool life combined with minimal effort.

- Extremely versatile: ideal for the grinding, correcting, cleaning and optical smoothing of weld seams.

- Durable abrasive cloth: consistent performance down to the very last abrasive grain.

- Integral edge protection: prevents damage to the workpiece.

- Patented technology: combination of precision and durability.

Outstanding performance for demanding grinding work

V2 Edge CeramicAd

Specially developed for tough jobs on tempered steels and coated surfaces, the V2 Power flap disc offers an outstanding tool life and high precision.

- Innovative glass-fibre fabric carrier: stable and flexible for the best surface results.

- Patented flap shape: reduces noise and vibrations by 50%.

- Maximum sharpness: worn flaps are replaced by fresh ones, consistent quality.

- Versatile application possibilities: for machining radial and end faces, ideal for complex geometries.

- High removal rates: efficient and reliable, ideal for diverse applications.

Flexible for hard-to-reach areas

SLT flex CeramicAd

The SLT flex flap disc offers maximum flexibility and removal rates when machining hard-to-reach areas and uneven surfaces.

- High flexibility: ideal for uneven surfaces and hard-to-reach areas.

- Patented flap shape: reduced noise and vibrations, better surface results.

- Long-lasting sharpness: multi-layer abrasive coating for consistent performance.

- For use on radial and end faces: especially flexible grinding pattern when used on face ends, ideal for grinding fillet welds.

- Alternative to the grinding disc: more flexible and ideal for precise machining.

Efficient fillet weld machining

Choose your fillet weld specialist. Find out all about the various applications and advantages in our video.

Next level innovation at LUKAS

Maximum performance by exploiting every potential capability

“Our development department continuously creates new tools that enable exceptional performance.”

Innovation has been the core of our work at LUKAS for over 85 years. Our tools are being continuously developed and always keep pace with the latest technical knowledge. We are always analysing the market needs and develop precisely those solutions that are in demand at any given time. If these are not adequate, we will work with you to develop new, made-to-order tools. Please don’t hesitate to get in touch with us!

Dr. Fischer // Development

Find your perfect grinding solution for machining fillet welds! Use our made-to-measure products for precise machining of your fillet welds.

Do you have any questions about our products? We will be happy to advise you!

Haven’t you received a trial set of our fillet weld grinding discs yet? Request your set today and discover just how efficiently our grinding solutions can perfectly machine fillet welds.