For perfect results when chamfering hard-to-reach areas: reverse deburring with tools from LUKAS-ERZETT.

Efficient, precise processes and the use of premium quality tools are the core elements of modern production methods. They enable companies to cut their time and cost expenditures and develop their competitive advantages, in particular when chamfering hard-to-reach areas such as in steel, container and apparatus construction, in mould making in the glass industry, and in the aerospace industry. A key task here is reverse deburring, which involves the precise machining of the inner edge of bores or complex geometries while ensuring dimensional accuracy and high surface quality.

Requirements that can be fulfilled quickly and effortlessly for reverse deburring work in various industries using high-quality tools from LUKAS-ERZETT. Precisely, efficiently and reliably. On the inside edges of bore holes or other openings in pipes or containers – regardless of the material.

Chamfering and reverse deburring: indispensable preparation for subsequent work steps. And for safe, high-quality components

Chamfering and reverse deburring are crucial processes. The precise creation of a chamfered edge on workpieces removes sharp edges, creates a clean, even surface, and prepares components for subsequent work steps such as welding, assembly or painting. At the same time, preventing the risk of injuries or damage caused by sharp edges makes the workpieces safer. In other words, the quality of the machined workpieces is significantly enhanced with smooth transitions and precise edges. This ensures a flawless appearance for aluminium rims, for example, and also contributes to the durability and ideal functionality of pipes, containers and moulds in sectors such as glass production.

In addition, reverse deburring provides for greater efficiency and productivity in production processes. The simultaneous removal of burrs and creation of precise chamfers using high-quality machining tools and special solutions, such as those offered by LUKAS-ERZETT for many different industries, eliminates the need for time-consuming finishing work. This creates tangible added value.

Reverse deburring plays an especially decisive role in hard-to-reach areas such as the inside edges of bore holes, containers or complex geometries as it enables precise, efficient chamfering and reverse deburring of workpieces that are difficult to machine using conventional methods. In short: reverse deburring not only saves time, but also contributes to achieving a high quality and greater efficiency.

For greater efficiency and productivity: how premium quality tools optimise the chamfering and reverse deburring process

As with all other machining steps, the quality of the utilised tools makes a significant contribution to efficiency and productivity during chamfering and reverse deburring work. What’s more, they help to optimise the entire machining process and ensure top-class work results.

High-quality, precise cutting tools such as the reverse deburring tools from LUKAS-ERZETT enable precisely defined chamfers in hard-to-reach areas in pipes, housings or containers. The cutting edges ensure high removal rates without interruptions and the best surface results in the fastest possible time.

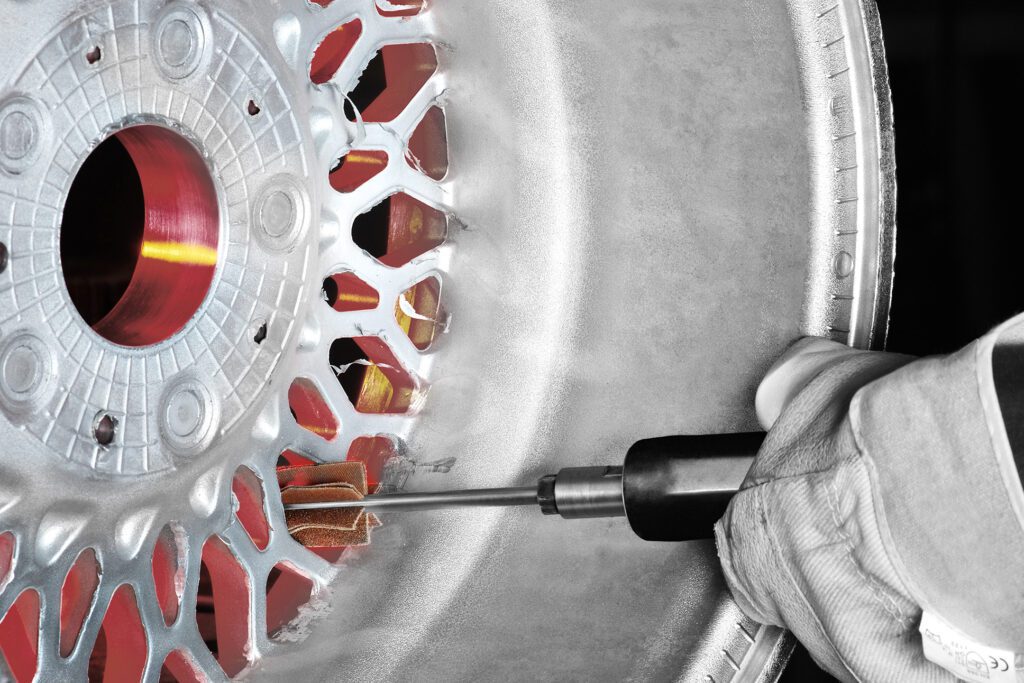

On all kinds of materials. Another example are the miniature mounted flap wheels from LUKAS-ERZETT, which ensure precision and efficiency when machining aluminium rims, producing moulds in the glass industry or machining bore holes, for instance. High-quality tools also have a longer service life, which means fewer tool changes, less time lost and lower costs throughout the entire production process.

In short: using high-quality tools such as LUKAS reverse deburring tools and LUKAS miniature mounted flap wheels pays dividends in many ways. They optimise the process reliability, reduce machining times and in doing so increase productivity – naturally without compromising on the quality of the workpieces.

Reverse deburring made easy. With innovative machining tools for hard-to-reach areas. Naturally from LUKAS-ERZETT

Premium quality milling, grinding, polishing, cutting, drilling and cleaning tools are the core competence of LUKAS-ERZETT GmbH & Co. KG, which has been supporting its customers from many different industries for over 85 years by developing and producing innovative and special solutions. Consistently high precision, quality and process reliability, together with low tool costs, are also top priorities for LUKAS-ERZETT when it comes to chamfering and reverse deburring.

Whether in steel, container and apparatus construction, mould making in the glass industry or in the automotive and aerospace industries – with innovative, high-quality machining tools such as the LUKAS reverse deburring tools and the LUKAS miniature mounted flap wheels, the company offers solutions that ensure efficiency, precision and high quality in daily use.

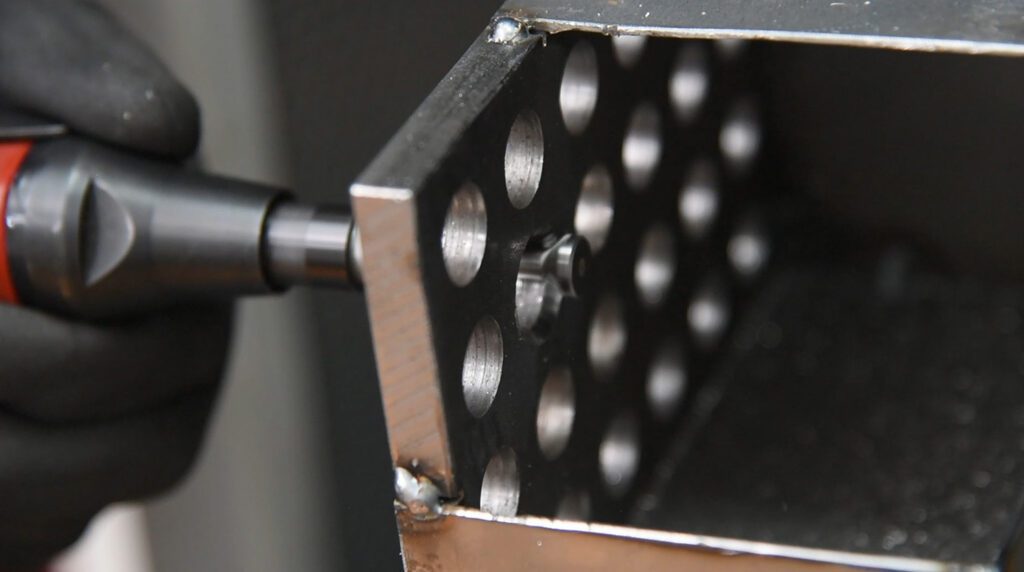

For example, the LUKAS HFT burr, specially developed for reverse deburring, can be used to effortlessly and quickly create precisely defined 45° chamfers in hard-to-reach areas in pipes, housings or containers. The long cutting edges of the reverse deburring tool do not require any interruptions and, with their cost-efficient single cut, offer the best surface results when machining cast steel, hardened and unhardened high-strength steels and stainless steel.

The LUKAS miniature mounted flap wheels made from abrasive cloth allow grinding of even the smallest areas of the workpiece, making tasks like machining of aluminium rims easy. They can even be used to machine very small inner bore and tube diameters. The LUKAS miniature mounted flap wheels produce perfectly rounded bore edges. This optimises the flow properties of the component or prevents damage to cables or lines routed through the opening. The regular aluminium oxide offers an impressively good tool life on many materials and cost-efficient working. All in all, with innovative solutions such as the durable LUKAS reverse deburring tools, which are available in different diameters, and the LUKAS miniature mounted flap wheels, LUKAS-ERZETT enables its customers to further optimise their chamfering and reverse deburring work in hard-to-reach areas.

See for yourself – and find out more about the high-quality LUKAS reverse deburring tools

Chamfering and reverse deburring work made precise and efficient – with its high-quality machining tools for different industries, tool manufacturer LUKAS-ERZETT tool manufacturer LUKAS-ERZETT offers impressive solutions that stand for greater efficiency, optimised production processes and a perfect surface quality.

The company’s experts are available by telephone or email to answer your questions and give you specific advice about chamfering and reverse deburring tools.