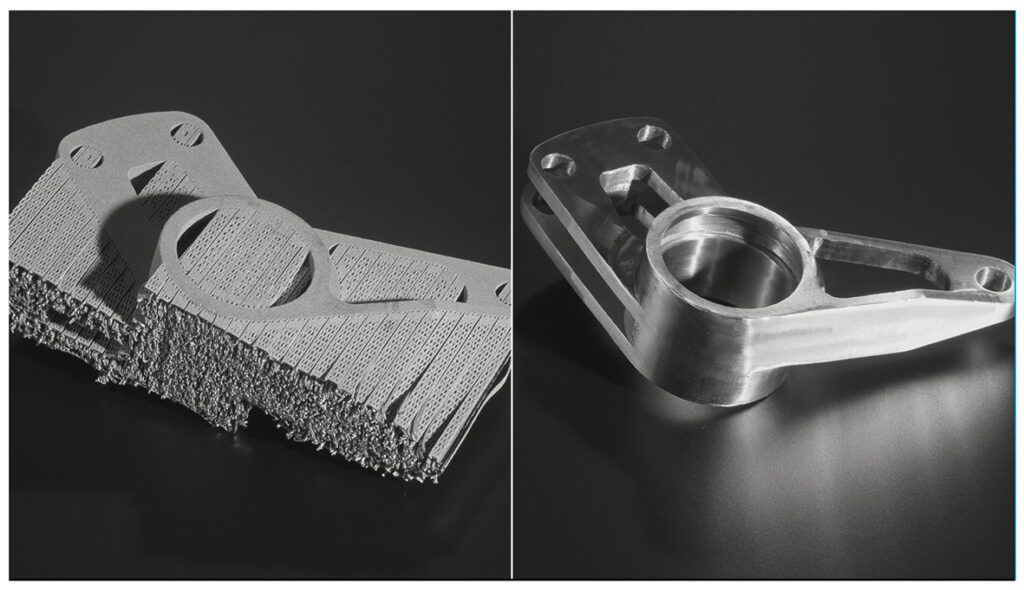

Additive manufacturing vs. subtractive manufacturing: make the most of the advantages of both processes with tools from LUKAS-ERZETT

Modern industrial production places high demands on precision, efficiency and design. Alongside subtractive manufacturing processes such as milling and grinding, additive manufacturing (3D printing) with processes like selective laser sintering (SLS) or selective laser melting (SLM) is playing an increasingly important role. Both subtractive and additive manufacturing offer specific benefits with regard to efficiency and competitiveness which can be ideally utilised with tools and special solutions from tool manufacturer LUKAS-ERZETT, for example in sectors such as the automotive and aerospace industries, medical technology or in machine, plant and tool engineering.

For more synergies in production processes: simply combine the strengths of additive manufacturing and subtractive manufacturing

Innovative production methods and processes have been helping to increase efficiency and competitiveness since the dawn of industrialisation. In addition to many further improved subtractive manufacturing processes, additive manufacturing has long offered enhanced optimisation potential to reduce costs and increase productivity.

Additive manufacturing (3D printing), for example, offers impressive design freedom, material efficiency and the capability to produce components with complex geometries, integrated structures and cavities quickly and efficiently – advantages that pay off in constructing prototypes and for small-batch production runs, for example. And not to forget: shorter development cycles and innovative, customer-specific solutions.

In contrast, subtractive manufacturing processes guarantee high dimensional accuracy, outstanding surface quality and process reliability in industrial series production scenarios. These processes stand for precision and long tool life in the automotive industry, the aerospace sector, in machine and plant engineering and mouldmaking for the production of all kinds of components with tight tolerances.

Tools such as those developed and manufactured by LUKAS-ERZETT for its customers are a key prerequisite for the successful deployment and optimum utilisation of the strengths of both processes – whether for robotic milling applications or for finishing 3D-printed parts.

Efficiency and precision: technologies, applications and advantages of subtractive manufacturing

As a significant element of modern production processes, subtractive manufacturing includes technologies such as milling, turning and grinding, as well as electrical discharge machining (EDM) and laser and water jet cutting. Thanks to state-of-the-art machines and the use of robots, these processes enable precise machining and repetitive precision, which are key factors where efficiency is concerned in series production scenarios.

Subtractive manufacturing also enables efficient and precise machining of many different materials such as steel, cast materials, non-ferrous metals like aluminium, as well as plastics and composite materials.

Further advantages are dimensional accuracy, excellent surface quality and functionality as well as the durability of the end products, which can be achieved, for example, by using premium quality milling, grinding, polishing, cutting, drilling and cleaning tools and special solutions from LUKAS-ERZETT. These are all reasons why subtractive manufacturing is used in many sectors such as the automotive and aerospace industries, mechanical engineering and medical technology.

To sum up, subtractive manufacturing offers reliable and cost-effective methods, particularly for metalworking companies, for producing high-quality components that meet the demanding requirements of modern industry.

Individual solutions with a future: technologies, applications and advantages of additive manufacturing

Thanks to the capability for building up complex components layer by layer using a wide variety of materials, additive manufacturing processes, often referred to as 3D printing, offer pioneering alternatives to conventional manufacturing processes. Additive manufacturing technologies include fused deposition modelling (FDM), stereolithography (SLA), selective laser sintering (SLS), direct metal laser sintering (DMLS) and electron beam melting (EBM) for metal parts.

Among other things, additive manufacturing processes enable the efficient and lighter production of components, using less material, with complex geometries, integrated cavities and grid systems, as well as lightweight structures. This also allows innovative design solutions to be made that are difficult to fabricate using conventional processes.

For example, 3D printing processes are used in the automotive and aerospace industries, for tool and mouldmaking and in the medical technology sector. The results are components that are characterised by their high strength and low weight, complex tools with integrated cooling systems, through to patient-specific implants or prostheses.

In addition to freedom of design and reducing material waste, important advantages of additive manufacturing include the capability to quickly adapt to individual requirements. This means that development cycles can be markedly shortened, allowing prototypes and small batches to be produced quickly and cost-effectively.

LUKAS-ERZETT offers its customers a large selection of high-quality tools and special solutions for the particularly fast, precise and efficient, sometimes complex finishing of high-quality 3D-printed products, such as for removing supporting structures, smoothening stepping effects on bevels and radii, producing flat surfaces or cleaning bores and the final polishing.

In short: additive manufacturing is a forward-looking alternative process that complements existing manufacturing technologies and fosters innovation. This makes it an indispensable element of modern and efficient production processes.

Discover the perfect tools for your additive manufacturing now!

Additive manufacturing or subtractive manufacturing? Both! Tools and special solutions from LUKAS-ERZETT make you ideally equipped to implement them

Using new materials with enhanced properties, ongoing process optimisation and increasing the degree of automation, for instance by deploying robots – there are many ways to master the ever-greater challenges of industrial production and to combine goals such as low costs, the best possible quality and increased productivity. The basis for efficient manufacturing with subtractive processes is always to use the right tools. Whether for machining cast material, steel, non-ferrous metals or plastics and composites. With over 85 years of experience in developing and producing high-quality tools and special solutions for subtractive manufacturing, tool manufacturer LUKAS-ERZETT supports its customers with an extensive range of milling, grinding, polishing, cutting, drilling and cleaning tools and solutions, including for robotic applications. The LUKAS-ERZETT assortment also includes high-quality tools and special solutions that enable efficient subtractive finishing of 3D-printed parts made using the various additive manufacturing processes.

In other words, with tools from LUKAS-ERZETT you have the know-how to make your production processes future-proof and competitive so that you can fully exploit the advantages of subtractive and additive manufacturing.

Find out more now – and make the most of the advantages of additive and subtractive manufacturing methods with LUKAS tools

For applications in additive manufacturing and efficient series production processes using subtractive manufacturing methods: tool manufacturer LUKAS-ERZETT offers the right tool for handling practically every challenge in many different industries with its broad and deep product range.

Your best course of action: ask us for in-depth advice. The expert staff at LUKAS-ERZETT will be glad to help you by telephone or email. You can also find more information and an overview of the entire LUKAS tool range here: lukas-erzett.com/en/

The company’s experts are available by telephone or email to answer your questions and give you specific advice about chamfering and reverse deburring tools.