Milling, grinding and polishing tools for all vehicle parts – LUKAS-ERZETT with innovation and precision for the automotive industry

The automotive industry faces constant challenges, from optimising production processes to ensuring the highest levels of quality and safety. In this demanding environment, tool manufacturer LUKAS-ERZETT has established itself as a leading provider of state-of-the-art tool solutions with a clear focus on innovation and precision. With this focus and its long history of innovation, LUKAS sets standards in the manufacture of tools that fulfil the specific requirements of the industry.

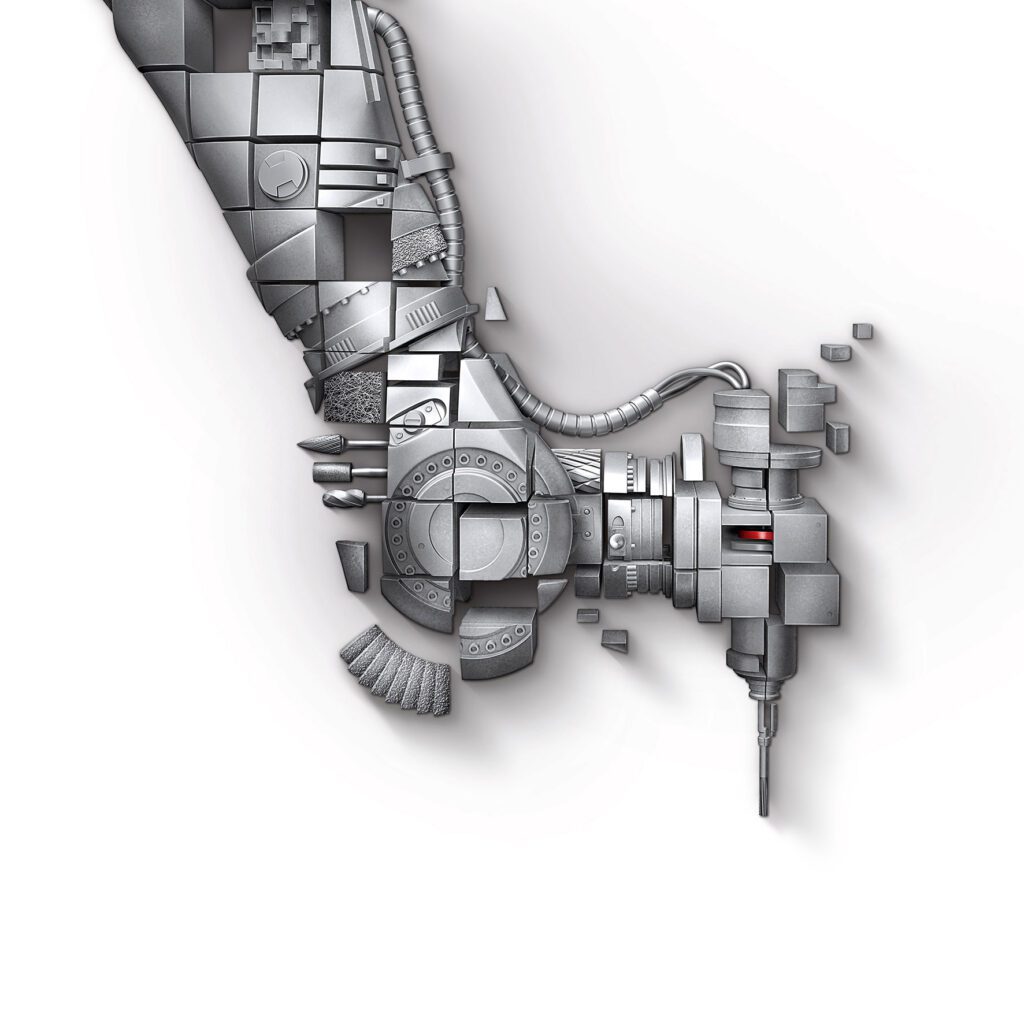

From rough machining through to creating a mirror finish: such tasks are no problem at all with the LUKAS-ERZETT tool portfolio. As a company in the automotive industry or a supplier, it offers you high-quality, high-performance tools and process solutions that contribute to achieving better quality and greater efficiency. These include milling and grinding tools for machining engine, transmission, axle and body parts, for example, as well as LUKAS polishing tools with which any challenge that can arise when finishing high-quality surfaces can be reliably mastered.

Modern vehicles are made from materials that have to meet the most demanding requirements. The LUKAS product range focuses on innovation and performance in order to satisfy the needs of today’s automobile manufacturers. As a long-standing expert in milling, grinding, polishing and cutting, LUKAS is a reliable partner for the automotive industry and its suppliers. With its tools and process solutions, LUKAS enables high-precision machining of cast parts, engine blocks, pistons, transmission gears, turbocharger housings, crankshafts, aluminium rims and other highly complex components.

The expertise of the development department at LUKAS consistently comes up with new tools for exceptional performance. Among the most abrasive tools on the market are the LUKAS iQ series grinding discs. These include flap discs with a multi-layer design for a long tool life even after intensive use. Other discs achieve even more exceptional removal rates with their patented overlapping flap shape and arrangement. LUKAS has made a name for itself with its developments – especially wherever tools with unusual capabilities are needed.

“More than just milling” was the development department’s aspiration with the LUKAS high-performance burrs. Machining aluminium requires special tools to obtain the best results. Fast-working, a long service life and infrequent tool changes. Applications such as deburring turbocharger housings or the large-scale machining of gears for use in transmission units are easily mastered with LUKAS deburring cutters which meet the most demanding requirements in terms of performance, dimensional accuracy and tool life. LUKAS offers tungsten carbide burrs with different coatings for applications requiring even greater efficiency. The LUKAS-ERZETT portfolio includes various high-performance burrs that are ideally tailored to aluminium machining applications.

Also available are naturally tools for processing plastics since these continue to play a growing role in automotive manufacturing. LUKAS-ERZETT offers the full spectrum of powerful, highly efficient tools. Processing a wide variety of composite materials is no problem either. Machining carbon fibre milled parts or plastics in conjunction with glass fibre, carbon fibre or aluminium sheeting is easy with the right LUKAS tools. LUKAS burrs are tailored to the respective materials and offer nothing but advantages with their specially developed and tested teeth geometries.

From milling and grinding to polishing – every tool meets the highest standards. The focus is not just on technology, but also on efficiency. LUKAS-ERZETT products help to optimise production processes and at the same time enhance the quality of the end products.

With production and sales locations spread around the world, LUKAS is not just a supplier of tools, but a global partner. The plants in England, Spain, China, the Czech Republic and South Africa provide for efficient supply chains to the automotive industry in various regions. Over 650 employees contribute to the company’s success with their expertise and dedication. Proximity to its customers, combined with a deep understanding of the specific challenges of the automotive industry, makes LUKAS an indispensable player.

The automotive industry demands top performance in all its facets, for which LUKAS-ERZETT supplies the matching tools. With over 80 years of experience in the manufacture of high-performance tools and the development of individual process solutions for milling, grinding, polishing and cutting applications, LUKAS-ERZETT offers automotive manufacturers and suppliers the best prerequisites for completing all steps in metalworking reliably, precisely and efficiently. With an impressive history of innovation, state-of-the-art products and a global presence, LUKAS is already the partner of choice for many companies in the automotive industry. The product recommendations and its clear commitment to quality and sustainability make LUKAS-ERZETT an indispensable player in this dynamic sector.