Abrasive caps: Leading-edge quality for many different applications

LUKAS-ERZETT is a world leader in grinding technology and offers an impressive range of high-quality abrasive caps. With its decades-long experience and continuous innovation work, the company from Cologne in the Oberbergisch district sets new standards with regard to quality and performance.

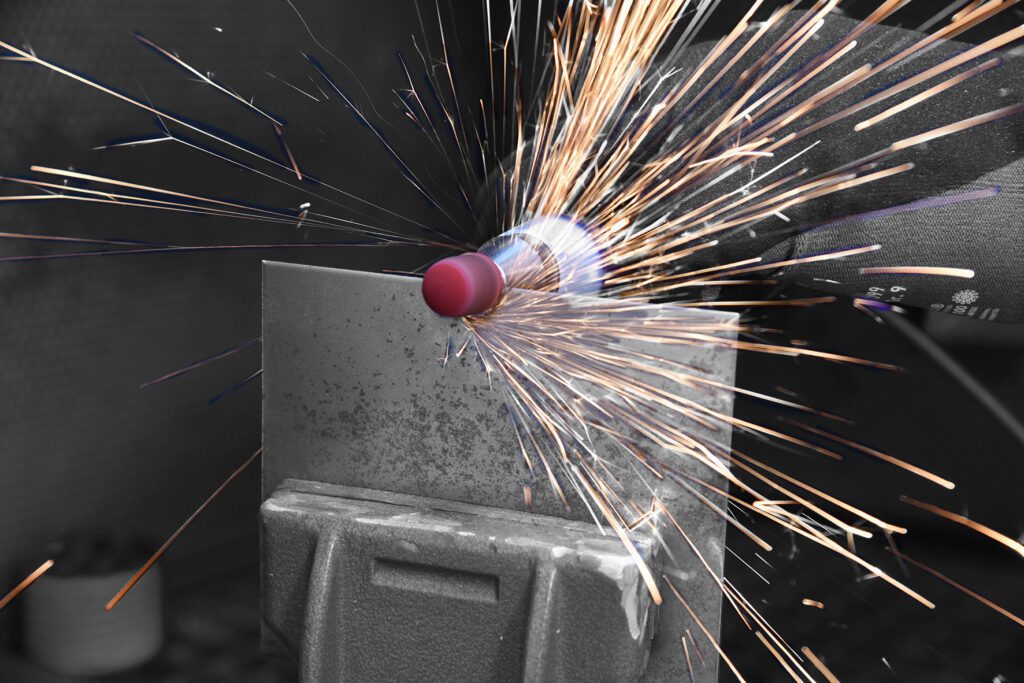

Exceptional quality and performance capability are the hallmarks of LUKAS abrasive caps. Thanks to state-of-the-art manufacturing technologies and high-quality materials, the abrasive caps achieve perfect results where material removal rates, surface quality and tool life are concerned. With their robust design, ideal abrasive grain dispersion and long tool life, they provide reliable results and minimise the work effort. Users can rely on the durability and efficiency of the abrasive caps.

The LUKAS range includes abrasive caps for many different applications. Whether in metalworking, mechanical engineering, the automotive industry or other sectors – optimised abrasive caps are available for practically every requirement. From coarse grinding to fine machining, the different variants offered by LUKAS provide for precise and efficient grinding systems.

In metalworking, the abrasive caps from LUKAS-ERZETT can be used for a wide range of applications. They are ideally suited for removing weld seams, deburring, and preparing surfaces before painting or coating, as well as for cleaning metal parts. With their high removal rates and precision, they facilitate not only efficient, but also high-quality machining. Whether tool steel, cast steel or titanium alloys – in the industry an increasing variety of extremely hard and tough metals have to be machined. The LUKAS SK Ceramic abrasive cap is a revolutionary tool for straight grinders that allows small parts to be machined and deburred with ease. Bonus: Extra-long tool life due to the self-sharpening effect!

The ceramic abrasive caps from LUKAS-ERZETT are used in mechanical engineering and mould making, and represent a valuable enhancement for tool inventories in all industries where hard metals are machined. They are excellent for grinding contours and working on hard-to-reach areas. Here, precise grinding work is indispensable for fabricating complex components and tools. These abrasive caps are perfect for grinding uneven surfaces, machining small parts, and for deburring and regrinding narrow radii. The abrasive caps can even be used on stainless steel as they barely heat up during grinding work.

To increase the performance of the LUKAS abrasive caps even further, we recommend using them together with a LUKAS abrasive cap mandrel. The dimensions of these high-quality tools are perfectly matched to the LUKAS abrasive caps for every application, which means extremely simple tool changes and secure holding during the work.

The LUKAS SKS Spezial abrasive cap has established itself as another problem solver in tool and mould making. Its high removal performance due to the regular aluminium oxide with abrasive surface layer, as well as its long tool life, make this abrasive cap a real game changer.

With the LUKAS abrasive cap portfolio, you will be prepared for every eventuality. The large selection of LUKAS abrasive caps offers different cap shapes and sizes, as well as the matching mandrels.

Thanks to their ergonomic shape and light weight, LUKAS abrasive caps enable precise and effortless working. Not only of a high quality, but also easy to use: The especially simple changing of the abrasive caps with the matching LUKAS abrasive cap mandrel offers greater efficiency and maximised productivity.

All LUKAS-ERZETT products are inherently an outstanding choice for all professional grinding work. As a technological leader in the manufacture of system solutions for milling, grinding, polishing and cutting, LUKAS experts are constantly working on developing products of the highest quality, performance and reliability for a multitude of applications. With their wide range of uses and impressive performance, they set standards in grinding technology.