Up to 8kg chip removal without changing tools

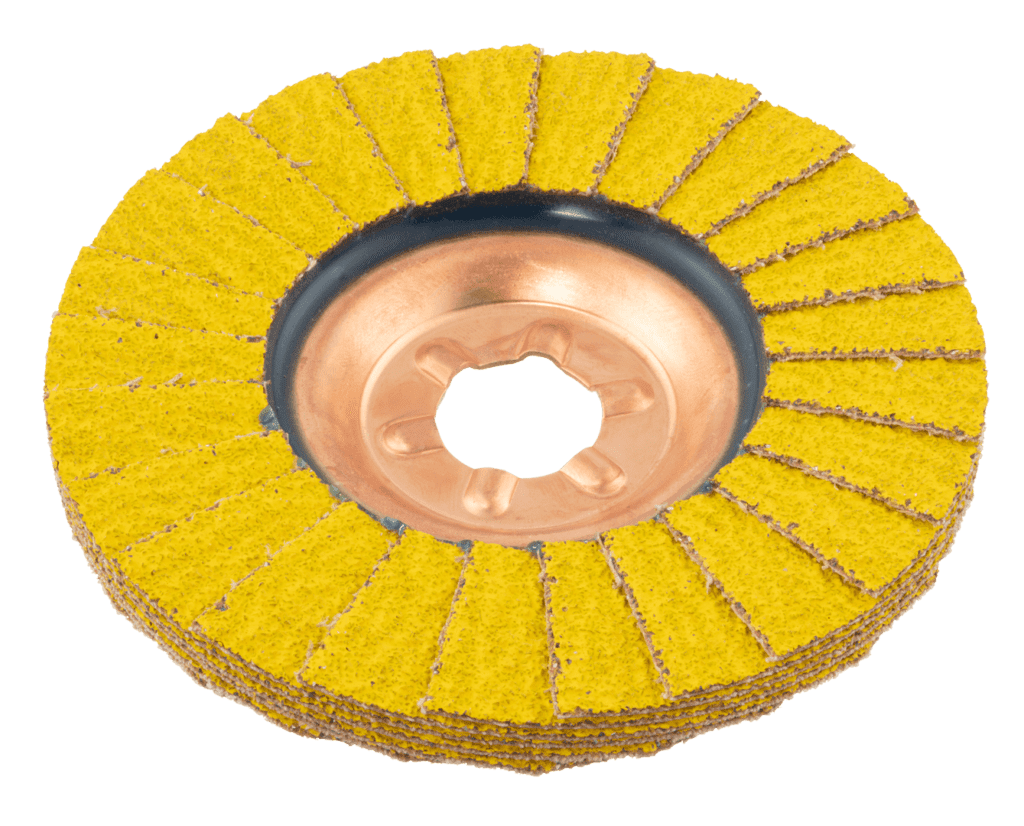

Unbeatable on steel: The HybridPerfectionCeramic4x from LUKAS-ERZETT

32,000 tons of steel, 10,000,000 ccm of weld seams and 55,000 metres of construction site joints: The Hochmosel Bridge spans the Moselle river at a height of 158 metres. Such a structure has so far represented a huge challenge for every grinding tool. But this is not the case with the new HybridPerfection with its state-of-the-art Ceramic4x abrasive cloth and patented sickle flaps: Just 9,825 of these mounted flap discs would be needed today. In comparison: The same work would require 78,600 standard discs (at 1kg chip removal).

The new HybridPerfectionCeramic4x from LUKAS combines a robust metal carrier disc with the sensational performance characteristics of the new, sickle flap-shaped Ceramic4x abrasive cloth. This provides users with a robust tool that will revolutionise working procedures, especially in shipyards and at large steel construction companies. Large quantities of steel can be quickly and ergonomically cut using this new tool with its phenomenal tool life.

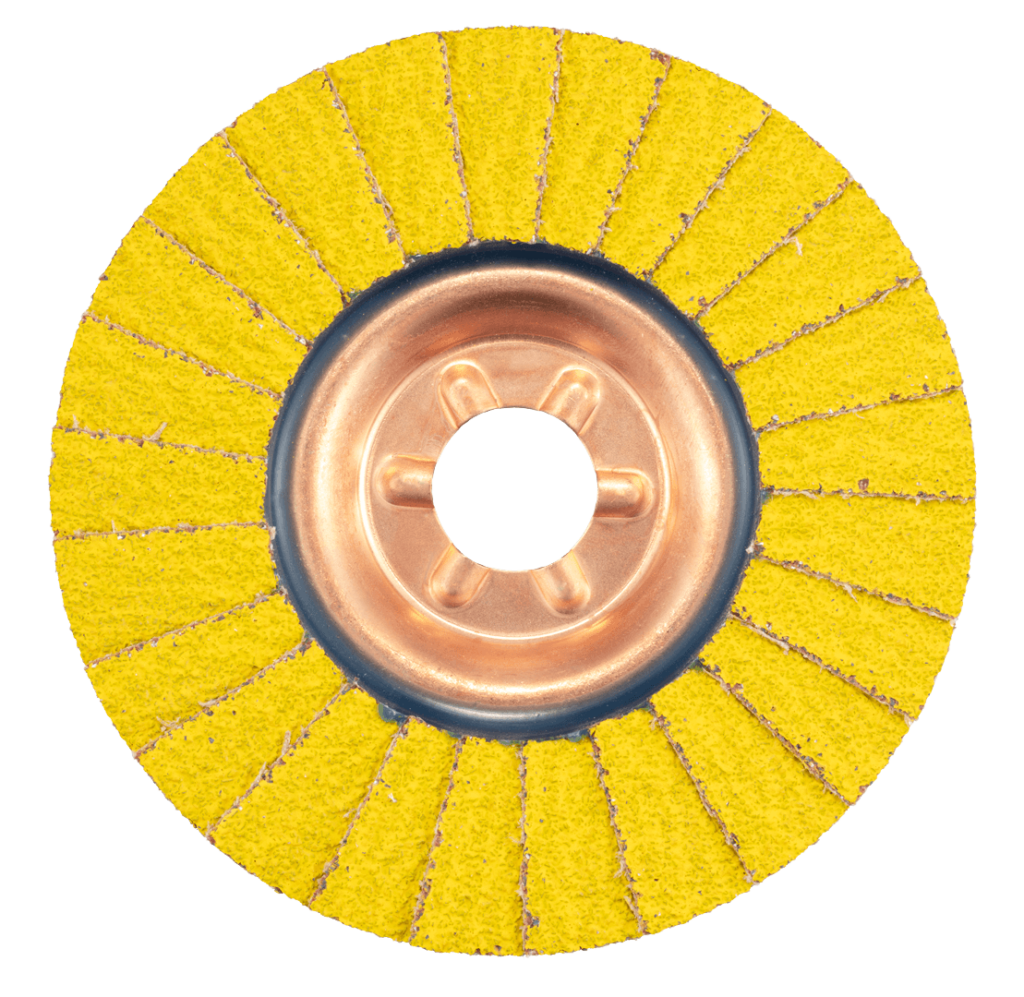

The new mounted flap disc, with a design that clearly stands out from the market standard, is the professional tool for the toughest applications on steel, marine steel, hardened steel and titanium. This yellow HybridPerfection Ceramic4x is characterised by faster material removal and an impressive tool life for coarse steel machining, as well as for grinding edges and weld seams.

Focused new and further product development

The HybridPerfectionCeramic4x mounted flap disc features the LUKAS patented flap shape with a flap arrangement that is optimised for high performance: Due to the high number of layers, over 70% of the abrasive particles are located in the outer area of the carrier disc. The innovative flap design, with which LUKAS as a flap geometry expert sets standards in the market, and the ideal alignment of the grinding particles on the tool allow for significantly more ergonomic working than with alternative tools such as resin-bonded rough grinding discs. Noise, vibrations and the required contact pressure are appreciably reduced for the user.

In combination with the latest new development – the high-performance Ceramic4x abrasive cloth – this creates the perfect tool for industrial metal machining. Thanks to the consistently high grinding performance, this tool can be used down to the very last grain and does not need to be replaced prematurely. Regardless of whether grinding structural steel or challenging materials: In future, the HybridPerfectionCeramic4x will always be the first tool of choice for chamfering, deburring, rust removal, smoothening, fettling and weld seam machining.

Long tool life and excellent price-performance ratio with double the performance

The HybridPerfectionCeramic4x specifically and consistently transforms the potential of powerful angle grinders into grinding performance. This ensures excellent utilisation of the abrasive material and a long tool life for the mounted flap disc. Designed for endurance, this innovation doubles the total removal rate compared to the most powerful standard discs, resulting in an outstanding price-performance ratio for every user.

Productivity and economic grinding

Workers and abrasives account for around 90% of the total cost of grinding using handheld tools. The largest percentage of the costs are swallowed up by wages alone. Time is therefore a critical factor in grinding work – and this must be shortened by using suitable tools. Not only does this cut down the costs – the better balance angle of the HybridPerfectionCeramic4x makes for more ergonomic, efficient and comfortable working, and reduces the constant physical strain on the worker while grinding. This means that operators can achieve a much better performance as less effort is required. Consequently, less pressure is exerted on the joints, there is less strain on the muscles, and the worker can recuperate more quickly between grinding operations.

The ideal quality tool

The correct and ideal use of quality abrasives for maximum material removal, coupled with an excellent technique on the part of the worker, allows for up to 8kg chip removal with a HybridPerfectionCeramic4x. This guarantees time savings due to the fewer tool changes and faster, more ergonomic grinding material removal. So here it is worth paying more than the average price for the flap disc. The added value gained through the time savings and the durability of the material pays off.

The interplay between good grinding economy and choosing the right tool – the SLTT HybridPerfectionCeramic4x flap disc – yields this wealth of benefits. Test it now and convince yourself!

Place request for HybridPerfectionCeramic4x: https://lukas-erzett.com/shop/en

About LUKAS:

LUKAS – NEXT LEVEL SOLUTIONS.

As a technologically leading manufacturer of powerful and innovative milling, grinding, polishing and cutting tool solutions, LUKAS-ERZETT GmbH & Co. KG, based in the greater Cologne area, always focuses on the requirements of its customers and the latest developments in many different industries. AGILE, SUSTAINABLE, RELIABLE and FUTURE-ORIENTED – LUKAS thinks further, develops tailor-made solutions, and is always one step ahead of market requirements. This focus gave us the lead early on in the market and still does to this day.

All of the products that we manufacture and sell stand for outstanding quality characteristics such as powerful working, a long service life, excellent ergonomics and the very best results. If standard solutions don’t suit, we develop customised solutions to satisfy every application. This way, both your products and ours will always be ready for whatever the future holds.

LUKAS at the cutting edge of a global industry

With around 700 employees, state-of-the-art production sites in Germany, the Czech Republic and South Africa, a huge wealth of experience and a broad product range, LUKAS is firmly established in the markets. We are internationally active with branches and representatives on every continent. With over 80 years of experience, we produce system solutions for use in the automotive, aerospace, energy and construction industries, as well as for tradespeople.