High-quality tools for machining castings – LUKAS-ERZETT offers solutions for efficient and precise machining

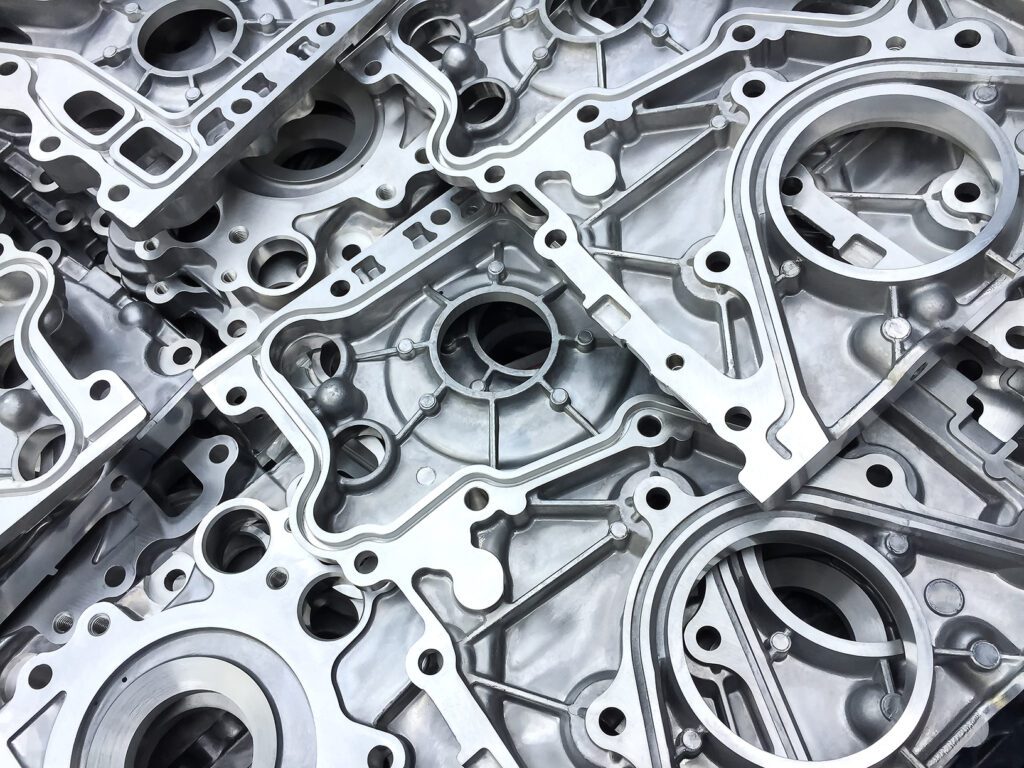

Foundries probably continue to play a much more crucial role in modern component manufacturing than one might suspect. The machining of castings is an important step in the production of parts for numerous industries. For example in the automotive industry, where cast materials are used for assemblies including engines, transmissions and brakes. In the aerospace industry, cast materials are essential for producing aircraft components such as engines and wings. In the medical field, cast materials are used for implants and prostheses. The machining of castings is therefore an indispensable part of today’s manufacturing processes. In order to carefully remove edges, castings and other traces of the manufacturing process after casting, special tools such as burrs, mounted points or cutting and grinding discs are used for precise and fast machining.

High-quality tools, especially the burrs, mounted points and grinding discs from LUKAS-ERZETT, are crucial for successfully and precisely machining cast materials. Thanks to their high material removal rate and durable quality, LUKAS tools enable fast and effective machining without compromising the surface quality. The type and quality of tools play a decisive role, especially in the machining of castings. High-quality tools provide for efficient machining, which in turn enhances the product quality and in the long term cuts down machining and manufacturing costs.

An example of such a top-quality tool solution is the LUKAS Cast burr series. Burrs for aggressive machining of cast materials sometimes have a tendency to break teeth. This is not true for these burrs, which were specially developed to handle such loads. Thanks to their faceted toothing, the robust Cast burrs from LUKAS achieve a high material removal rate even during manual machining, and can be guided smoothly and evenly with minimal vibration. The proven tungsten carbide quality and a reliable soldered joint round off the tool and ensure productive and reliable working.

After the casting parts have been milled, they are finely machined using mounted points. The characteristics of the various types of cast materials are normally determined by their carbon content and the way in which the carbon is removed from the material structure. Cast materials are generally rough machined. The skin contains inclusions of sand from the casting process; large burrs, sprues and risers, holes and cracks must all be removed by grinding. These areas to be ground are often somewhat inaccessible.

This is where the LUKAS mounting points for machining cast materials come into play. In three qualities, they declare war on the cast surface:

NK-BA hard, made from regular aluminium oxide in a resin bond; HK, a mixture of white and regular aluminium oxide; and MK, a mixture of pink and regular aluminium oxide.

LUKAS mounted points for grinding cast materials feature special grain combinations and tough bonding, and deliver excellent performance in the following applications:

- Deburring

- Fettling

- Smoothening

- Finishing of repair welds

- Removing holes and cracks

The aggressiveness of the abrasive grain and the smooth running of the mounted points allow for an ergonomic method of machining requiring minimum force. Also ask for mounted points with particularly long shanks. These allow you to effortlessly machine hard-to-reach areas in the component without having to find your own, usually unreliable and less ergonomic, extension solution for short mounted points.

The LUKAS mounted points in the qualities HK and MK were specially designed for cast materials. Their grain mixtures and resilient bonding agents are especially suitable for powerful and sustained working on cast steels. Fast grinding of sprues and burrs is no problem at all with these tools from LUKAS. Like many other LUKAS tools, their particularly smooth running characteristics provide for even, gentle and effort-saving work.

Contrary to some conceptions, the machining of castings is a constantly evolving field. New technologies and innovations play a decisive role here. One example of such an innovation is the use of robots for machining cast materials. Robots can increase the efficiency of production processes and improve working conditions for employees. They can also deliver precise and repeatable results. The use of 3D printing technologies in machining castings also has the potential to improve the process and cut costs.

The manufacture of engine blocks, gear box casings, cylinder heads, frames, stands, machine slides, gears, crankshafts, pump and turbine housings or machine tool components, for example, requires high-quality cast metal parts.

Premium quality tools are required to machine the high-quality metal castings to perfection. With its wealth of over 85 years of experience and expert know-how, LUKAS-ERZETT has developed an extensive special range of tools for machining cast parts in the fields of grinding, milling, polishing and cutting. The range includes mounted points, cutting discs and burrs that have been specially developed for finishing cast materials. The tools from LUKAS-ERZETT convince not only on account of their high-quality, but also with their innovative technology. For example, the VDC diamond cutting discs are available with special diamond coatings designed specifically for cutting grey iron (GG, GGG). They are particularly aggressive and powerful and offer extreme durability when machining GFRP and mineralisations. Furthermore, many other LUKAS tools are also suitable for use on robots for even greater production efficiency. With these high-quality tools and the latest technologies for machining castings, manufacturers of high-quality cast metal parts can be sure that they will always achieve the best possible results.

Especially flexible: The LUKAS C24S-BF cutting disc is a universal cutting tool for expertly machining concrete, stone and cast material. Especially in structural and civil engineering, for new buildings or structural alterations on existing ones and in road construction, special tools are required that allow the greatest possible flexible machining of many different building materials. From brickwork, cast pipes or concrete supports – LUKAS cutting discs for stone, concrete and cast material cut reliably and quickly. They are the perfect alternative for tradespeople who do not regularly use diamond cutting discs. The high proportion of silicon carbide in the cutting materials provide for a strong cutting performance. Foundries in particular prefer the LUKAS C24S-BF cutting disc for effortless and effective fettling. Risers and sprues can be easily and cleanly removed, while inclusions and flaws in the surface can be machined without any effort at all.

LUKAS-ERZETT GmbH & Co. KG, based near Cologne, specialises in the production and sale of grinding, milling, polishing and cutting tools, as well as power tools. It also offers consulting services and an extensive range of accessories. The extensive LUKAS-ERZETT product range offers you a wide selection of professional solutions for milling, grinding, polishing and cutting – for the casting industry as well!

More information can be found at https://lukas-erzett.com/de/branchenloesungen/giessereien/