LUKAS tools with self-sharpening effect save time in the workflow and money in use

LUKAS-ERZETT GmbH & Co. KG, as one of the technological leaders in the market for high-performance and groundbreaking milling, grinding, polishing and cutting tool solutions, stands for pioneering innovations in the tool industry. Based in the greater Cologne area, this traditional German company always focuses on customer requirements and the latest developments in a broad range of industries worldwide. One outstanding example of LUKAS quality is the ceramic grain with self-sharpening effect.

The LUKAS ceramic abrasive cap is an established solution that enables precise machining of even the hardest metals. The abrasive cap with ceramic grain has been specially developed to meet the ever increasing demands of the industry. The ceramic abrasive caps represent a valuable addition to the tool stock for all industries in which hard metals are machined. These include tool and mould-making and the demanding mechanical engineering, steel construction and aerospace industries. A decisive advantage of the LUKAS ceramic abrasive caps is their versatility. Available in four different shapes, it is perfect for various applications such as grinding uneven surfaces, deburring and regrinding tight radii. It also enables precise machining of weld seams and is even suitable for machining stainless steel on account of the low heat build-up during grinding.

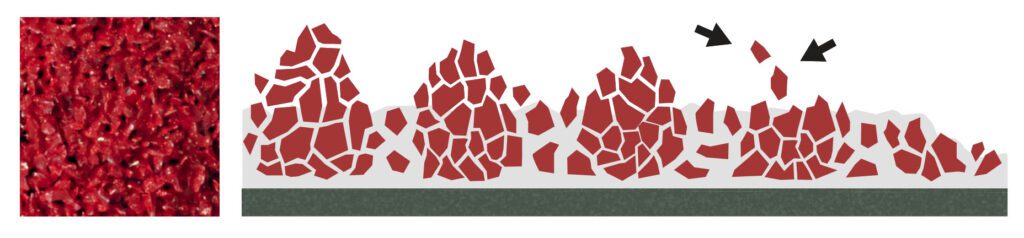

The complex innovation behind the self-sharpening effect can be simply explained. Worn grinding particles break off and expose new particles with fresh, sharp cutting edges – the abrasive cap remains as sharp as new for a long time.

This effect is particularly useful when machining materials such as tool steel, cast steel or titanium alloys. This requires exceptionally hard and tough tools. LUKAS tools with ceramic grain easily satisfy these requirements. Not only do they offer outstanding performance, which is particularly characterised by their self-sharpening effect. This innovative ceramic grain also ensures that the LUKAS abrasive caps, flap discs, mounted flap discs, fibre discs, abrasive discs and abrasive rolls equipped with it stay sharp for a very long time, even in the most challenging situations. The practical self-sharpening effect of LUKAS ceramic grain products not only makes for easier workflows with them, but also results in considerable savings in tool costs. Thanks to the self-sharpening effect, a tool life several times longer than that of conventional grinding tools is achieved. This means that tool changes are required much less frequently, which can hugely reduce the overall costs of a project.

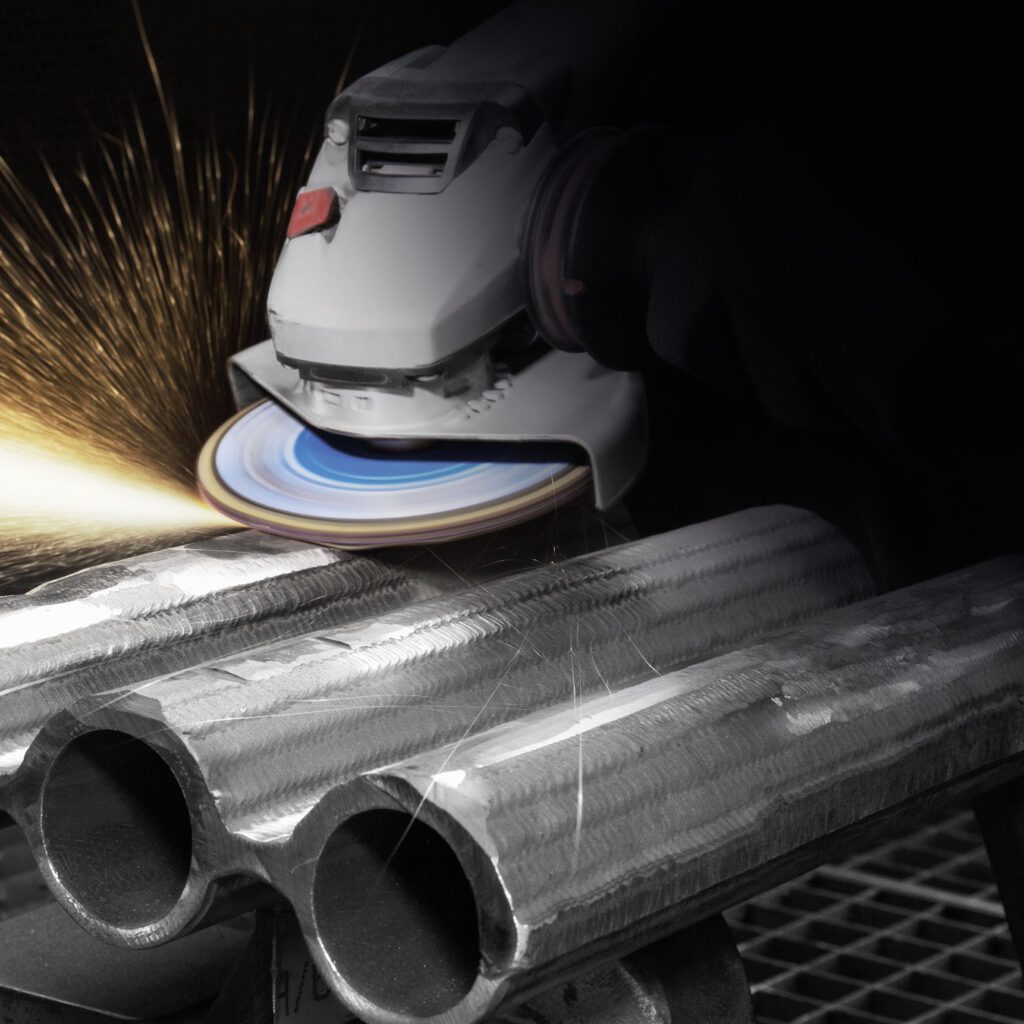

Another remarkable LUKAS product that utilises the self-sharpening effect is the V2 Power Ceramic mounted flap disc. This grinding disc combines the self-sharpening ceramic grain with a flap shape patented by LUKAS. This combination ensures a consistent performance level over the tool’s entire service life. The LUKAS V2 Power Ceramic mounted flap disc is ideal for the most challenging machining work and the toughest applications. Especially robust and efficient, it enables precise machining of materials such as tempered steels, titanium, stainless steel and many more. The self-sharpening effect of the ceramic grain ensures a perfect grinding performance and at the same time, cuts tool costs due to the less frequent tool changes.

The LUKAS grinding disc with ceramic grain is perfectly suited for the highly productive machining of steels. Thanks to its fast but cool cutting capability, it can machine Inox without any blue discolouration whatsoever. And it has an incredibly long tool life thanks to the self-sharpening effect. The same characteristics can be found with the LUKAS cutting discs with ceramic grain for the highly productive cutting of steels.

LUKAS ceramic grain tools with the self-sharpening effect offer innovative solutions for machining the most challenging materials. Hardened and wear-resistant steels, titanium alloys, weld seams and hard coatings are no longer a problem in metalworking with this grain. Even the hardest materials can be precisely and efficiently machined, while the products also help to reduce the overall costs thanks to their long tool life. With their innovative technology and top-of-the-class performance, LUKAS ceramic products are the first choice for professionals in the industry.

Our innovation and development team has many years of experience and a profound knowledge of our customers, their production processes and the industry. With this know-how, LUKAS consistently sets itself new goals to make milling, grinding, polishing and cutting with the “Made in Germany” quality seal even better. LUKAS unswervingly pursues the goal of combining quality and safety with future-oriented answers.