Articles from 2025

News, product presentations and trends

Considerably better performance and significantly lower costs with CBN mounted points and diamond mounted points & files from LUKAS-ERZETT.

Considerably better performance and significantly lower costs with CBN mounted points and diamond mounted points & files from LUKAS-ERZETT. CBN and diamond tools, on account of their extreme hardness, are much better than conventional abrasives for tasks such as machining…

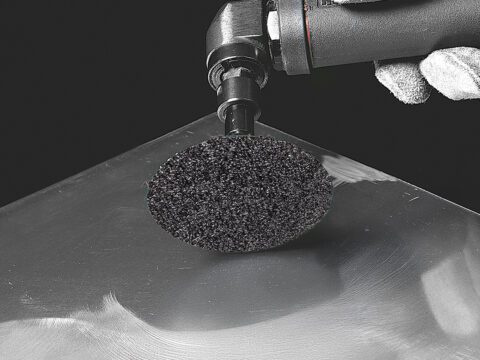

Flexible and efficient: the self-adhesive PSK abrasive discs from LUKAS-ERZETT are easy to handle and deliver strong performance.

Efficient grinding made easy with flexible tools: the extremely flexible self-adhesive PSK abrasive discs from LUKAS-ERZETT combine precise grinding results with quick and easy tool changes. Thanks to their advanced bonding technology, they can be fitted in seconds without tools. The self-adhesive LUKAS PSK abrasive discs are ideal for universal grinding and deburring work on steel and stainless steel, as well as for machining challenging materials such as titanium, aluminium and ceramics. They also perform a wide range of tasks precisely and reliably in branches such as the aerospace industry and for tradespeople. In short: LUKAS-ERZETT also offers its customers the usual high quality and simple, safe and efficient handling when grinding using flexible tools such as the self-adhesive PSK abrasive discs.

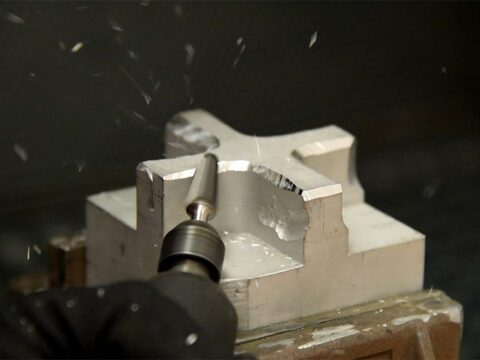

Additive manufacturing vs. subtractive manufacturing: make the most of the advantages of both processes with tools from LUKAS-ERZETT

Modern industrial production places high demands on precision, efficiency and design. Alongside subtractive manufacturing processes such as milling and grinding, additive manufacturing (3D printing) with processes like selective laser sintering (SLS) or selective laser melting (SLM) is playing an increasingly important role. Both subtractive and additive manufacturing offer specific benefits with regard to efficiency and competitiveness which can be ideally utilised with tools and special solutions from tool manufacturer LUKAS-ERZETT, for example in sectors such as the automotive and aerospace industries, medical technology or in machine, plant and tool engineering.

Precise woodworking in foundry pattern making: how milling tools from LUKAS-ERZETT improve quality and efficiency.

In foundry pattern making, the master pattern determines the quality of the subsequent casting. When making moulds from wooden models, efficient working methods, high dimensional accuracy and perfect, smooth surfaces are essential. The key to this, among other factors, lies in using the right tools. For example the Wood tungsten carbide burrs from LUKAS-ERZETT, which are available in different shapes. The tungsten carbide rasp burrs from LUKAS enable clean, controlled work, even with complex shapes. Thanks to their special geometry and design, LUKAS tungsten carbide burrs from the Wood series are ideal for achieving fast feed rates and high removal rates, enabling shorter machining times. A clear benefit for everyone who has to meet the highest requirements in foundry pattern making.

Fault prevention when cutting: typical milling faults and their solutions

Alongside many other influencing factors, precise milling processes also determine production quality and efficiency in the metalworking industry. Even small faults such as incorrect speeds or excessive applied grinding pressure can have serious consequences when milling material. Some typical sources of faults when cutting materials and their practical solutions are described below to sensitise everyone concerned with this important topic to support optimum process reliability – and in doing so help to permanently achieve a high surface quality during milling and to extend the tool life. One basic requirement is to use high-quality tools such as those offered to its customers by LUKAS-ERZETT.

For perfect results when chamfering hard-to-reach areas: reverse deburring with tools from LUKAS-ERZETT.

For perfect results when chamfering hard-to-reach areas: reverse deburring with tools from LUKAS-ERZETT. Efficient, precise processes and the use of premium quality tools are the core elements of modern production methods. They enable companies to cut their time and cost…

More removed material. More endurance. More power. The V4 Purple Power lamellar flap disc from LUKAS-ERZETT.

More removed material. More endurance. More power. The V4 Purple Power lamellar flap disc from LUKAS-ERZETT. Experience grinding at the highest level. With the V4 Purple Power lamellar flap disc, LUKAS-ERZETT offers its customers a durable grinding tool that has…

The PSG and PSR self-clamping abrasive discs from LUKAS-ERZETT: easy handling, professional surface finishing and maximum efficiency

Typical LUKAS-ERZETT: the PSG and PSR self-clamping abrasive discs combine precise grinding performance with maximum user comfort and efficiency. Thanks to the innovative self-clamping technology, they can be fitted quickly and without using tools. This creates tangible added value and supports smooth-running workflows without time losses. Whether for general grinding and deburring work or machining hard-to-cut metals and alloys: the LUKAS PSG and PSR self-clamping abrasive discs cover a wide range of applications and ensure first-class results. In handicraft, in industry – and wherever efficiency counts. Consistently high precision, quality and process reliability, as well as low tool costs, are also top priorities for LUKAS-ERZETT when grinding using flexible tools such as the PSG and PSR self-clamping abrasive discs with the quick-change system.

Secure grip, precise grinding, maximum flexibility and surface quality – all hallmarks of the PSH self-fixing abrasive discs from LUKAS-ERZETT.

The self-fixing PSH abrasive discs from LUKAS-ERZETT combine a reliable grip with high efficiency and easy handling. Thanks to the modern hook and loop fastening system, the self-fixing PSH abrasive discs can be mounted quickly, securely and without tools, while also offering a firm hold. Whether for deburring and chamfering work, machining weld seams, removing paint and rust, or fine grinding and polishing, the PSH abrasive discs are available in many grit sizes and enable precise, clean results on many different materials such as steel, cast material, aluminium, plastics or wood. Extremely good polishing results can be achieved with the fine grit sizes 800 and 1,200. While LUKAS is otherwise known for its very small polishing tools, the PSH discs are suitable for larger surfaces and can be used on eccentric or angle grinders. As with all flexible abrasives from LUKAS-ERZETT, quality and efficiency are paramount. For industry, trade and anywhere else that requires efficient and reliable grinding processes.

Three tools, one goal: perfect fillet weld seams.The new LUKAS tools for machining fillet welds

The machining of fillet welds is extremely demanding in terms of precision, material removal and surface quality. Specialised tools are indispensable for ideally smoothing welded joints, removing weld spatter and achieving an even surface. LUKAS-ERZETT offers professional solutions with the U-Edge Pro fillet weld grinding disc, the V2 Edge CeramicAd lamellar flap disc and the SLTflex CeramicAd lamellar flap disc. These high-quality tools will help you achieve perfect results when machining fillet welds. Quickly, precisely and efficiently.