How robots and LUKAS-ERZETT carbide burrs are the key to more efficient deburring and increased productivity

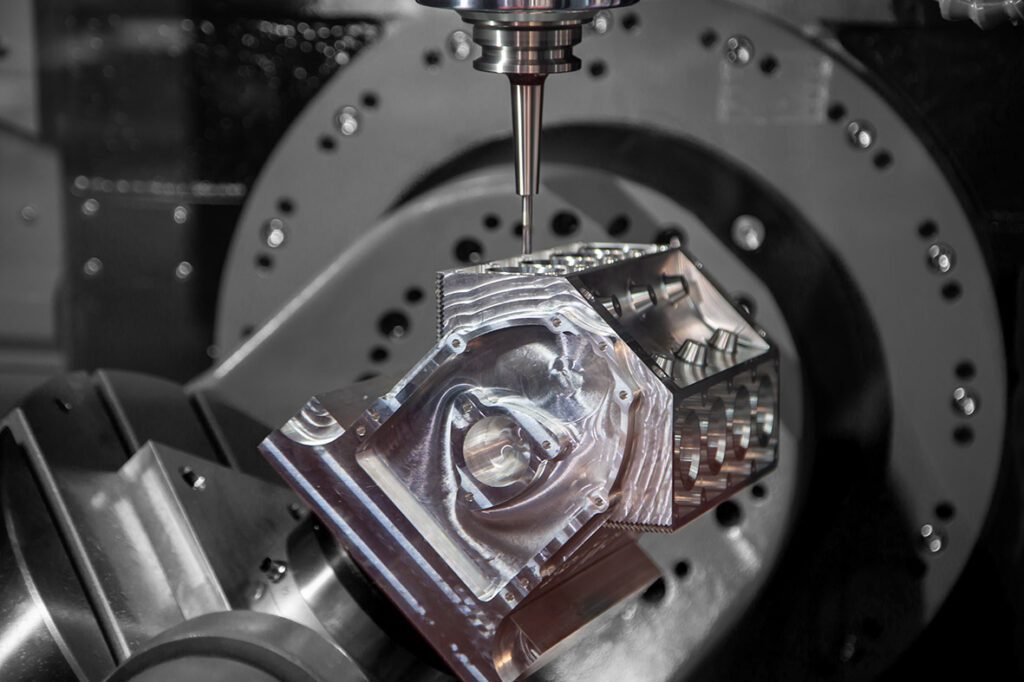

Efficiency plays a decisive role in today’s production processes. Time and cost savings coupled with maximum precision are vital if a company is to stay competitive. A key process step is deburring – a task that requires not only precision but also consistent results.

The solution? Automation with robots. With their high repetitive precision and reliability, robots enable both simple and highly demanding deburring tasks to be carried out efficiently on many different materials. High-performance tools specially designed for intensive use with robots are indispensable here – such as the carbide burrs from LUKAS-ERZETT.

Robotic deburring is in greater demand than ever in most industries, helping to reduce costs, boost productivity, and optimise product quality and reliability.

From the automotive industry to the aerospace sector, machine, plant, tool and mould construction, through to the furniture industry or medical technology and electronics, robotic deburring offers distinct advantages.

In addition to the efficient use of resources, these also include high process reliability and a consistently outstanding surface and workpiece quality, for example when deburring precision components such as gear wheels or turbine blades. The capability for multi-process machining and automatic tool changes can also help increase efficiency. This applies in practically every industry and to the various machining materials such as cast material, steel and stainless steel, non-ferrous metals like aluminium, as well as plastics, composite materials and wood.

However, state-of-the-art robots designed for handling the machining materials and workpieces are just one prerequisite for achieving the desired efficiency, productivity and quality goals. Another crucial factor are the tools with which the robots perform their tasks, such as the versatile, high-performance carbide burrs developed by LUKAS-ERZETT for use with robots.

LUKAS milling tools for stationary machining actively help businesses improve and build on their competitive advantage gained through the use of robots for deburring work

With over 85 years’ experience in the development and production of first-class tools and special solutions for milling, grinding, polishing, cutting, drilling and cleaning work, LUKAS-ERZETT GmbH & Co. KG also offers cutting-edge, high-performance solutions for robotic deburring systems. Whether for deburring cast material or gear wheels, machining non-ferrous metals such as aluminium, or deburring plastics and workpieces made of carbon and glass fibre.

LUKAS-ERZETT helps its customers from various industries make best use of robot systems with a wide range of innovative and high-performance carbide burrs.

The burrs, which are often specially developed for stationary use, are available in many shapes, head diameters and lengths, as well as with different tooth configurations and shank diameters. In addition, LUKAS-ERZETT carbide burrs are available with various high-quality coatings for achieving the best possible surface quality and process reliability. This increases their wear resistance, reduces the machine loads and improves the chip removal rate, for example.

LUKAS carbide burrs are also available with a stop ring for optimising the workflow within the automated processes. This enables the burrs to be positioned in the robot cell faster and more precisely. LUKAS carbide burrs are also available as clockwise or anti-clockwise rotating versions for scenarios where the burr’s direction of rotation needs to be adjusted for process-related reasons, in order to achieve perfect results.

In short: LUKAS carbide burrs are a byword for the best possible efficiency, process reliability and quality when used with robots as well.

Cast, Z9 Alu, CarbonCut, Composite – these are just some of the LUKAS carbide burrs that have made a name for themselves with their impressive performances in robot applications

Deburring, especially robotic deburring, is all about the details. Or rather the right tool. After all, a robot can only really exploit its full performance potential if it is fitted with the best tools. We would therefore like to briefly present a small selection of carbide burrs from LUKAS-ERZETT, whose outstanding characteristics can significantly increase the efficiency, quality and reliability of your machining processes.

Cast burrs for cast materials

The LUKAS Cast carbide burrs are precision tools that have proven their immense value in cast deburring work with industrial robots in particular. Thanks to its coarse toothing, the Cast burr for cast materials achieves high removal rates in a very short time. The proven LUKAS carbide quality, the high-quality steel shaft and the long-lasting sharp and robust cutting edges ensure a long tool life and the best possible results when deburring cast materials using robotic applications.

Details at a glance:

- High chip volume in just a short time thanks to the coarse toothing for quick working

- Robust cutting and toothing prevent breakouts and save valuable time

- Faceted toothing for perfect surface results

- No dangerous shank breakage thanks to high-quality steel shank

Z9 Alu burr with LUKAS LightFlow coating for deburring aluminium

The LUKAS Z9 Alu burr with the LightFlow coating is razor sharp, making it ideal for machining aluminium using robotic applications. The LUKAS LightFlow coating extends the service life of the burr fivefold and reduces friction between the tool and the material surface. Thanks to its coarse single cut and bevelling, the LUKAS Z9 Alu burr with LightFlow coating also offers impressively high chip volumes, rapid work rates and perfect surface finishes with robotic deburring applications.

Details at a glance:

- Aluminium deburring with razor-sharp cutting edges

- Up to a fivefold longer tool life thanks to the LUKAS LightFlow coating

- Easy chip removal and high chip volumes combined with excellent friction and non-stick properties

- Faceted toothing for perfect surface results

CarbonCut burr series for robot-aided, high-tech carbon machining

The LUKAS CarbonCut burr series easily masters the stationary milling, sawing and drilling (dipping) of premium high-tech materials such as carbon fibre-reinforced lightweight materials (CFRP). The result: perfect surfaces and top-class edges on the workpiece. The LUKAS CarbonCut also produces impressive results when machining composite materials such as GFRP and aluminium structures, for example thanks to its optimised chip removal capability and extremely sharp cutting edges. Last but not least: the low friction on account of the thin, smooth and extremely hard high-performance coating. In short: it is simply perfect for robotic applications.

Details at a glance:

- High cutting stability for milling carbon, CFRP or GFRP

- Extremely sharp cutting edges

- Low friction due to the thin, smooth and extremely hard, high-performance coating

- Fibre tears, protrusions or incomplete cut-offs and delaminating are a thing of the past.

- Long tool life in stationary use

Composite Coarse burr – the ideal tool for deburring plastics with robots

The LUKAS Composite Coarse carbide burr is designed for milling, sawing and drilling work. The fishtail tip can be used for drilling and face milling, while the extra-long cutting edge of the composite burrs is suitable for sawing as well as deburring. Alongside its durability, it is also impressively versatile, eliminating the need for multiple tool changes and making the burr ideally suited for use with robots.

Details at a glance:

- Ideal for deburring, drilling and sawing plastics

- Extremely versatile due to its long cutting element and fishtail tip

- Long tool life, fewer tool changes

- Ideally suited for use with industrial robots

LUKAS carbide burrs and robots: an unbeatable combination for advanced industrial production processes

Robotic deburring offers huge advantages in manufacturing. It not only enables consistently high precision, quality and process reliability, but can also contribute to reducing costs. The added value of automated solutions becomes clearly evident, for example, when machining materials such as cast material, aluminium, plastics and composites.

The carbide burrs from LUKAS-ERZETT, which were specially developed for use in robot systems, let users fully exploit the potential of robot-aided production. These LUKAS tools are characterised by their robustness, versatility and innovative finishings such as the LightFlow coating. They enable high removal rates, an extended tool life and perfect surface results. Even under extreme conditions, they make a decisive contribution to improving workflows and process reliability.

With its cutting-edge solutions such as the Cast burr (for cast iron), Z9 Alu (for aluminium), CarbonCut (for composite materials) and Composite Coarse (for plastics), LUKAS-ERZETT underlines its aspiration to support its customers in various industries with high-quality tools for robot applications. These solutions are decisive factors when it comes to optimising modern production processes.

Take the next step towards greater efficiency, quality and process reliability with robotic deburring applications – with the innovative carbide burrs from LUKAS.

Regardless of the industry, regardless of the material – tool manufacturer LUKAS-ERZETT offers you the right tool for mastering practically every challenge with robot applications. For greater efficiency, optimised production processes and perfect surface quality.

For questions and detailed advice on tools for deburring with industrial robots, please contact the LUKAS-ERZETT team by phone or e-mail.