Precise woodworking in foundry pattern making: how milling tools from LUKAS-ERZETT improve quality and efficiency.

In foundry pattern making, the master pattern determines the quality of the subsequent casting. When making moulds from wooden models, efficient working methods, high dimensional accuracy and perfect, smooth surfaces are essential. The key to this, among other factors, lies in using the right tools. For example the Wood tungsten carbide burrs from LUKAS-ERZETT, which are available in different shapes. The tungsten carbide rasp burrs from LUKAS enable clean, controlled work, even with complex shapes. Thanks to their special geometry and design, LUKAS tungsten carbide burrs from the Wood series are ideal for achieving fast feed rates and high removal rates, enabling shorter machining times. A clear benefit for everyone who has to meet the highest requirements in foundry pattern making.

The LUKAS Wood rasp burrs: precision tools for making foundry patterns and wooden moulds.

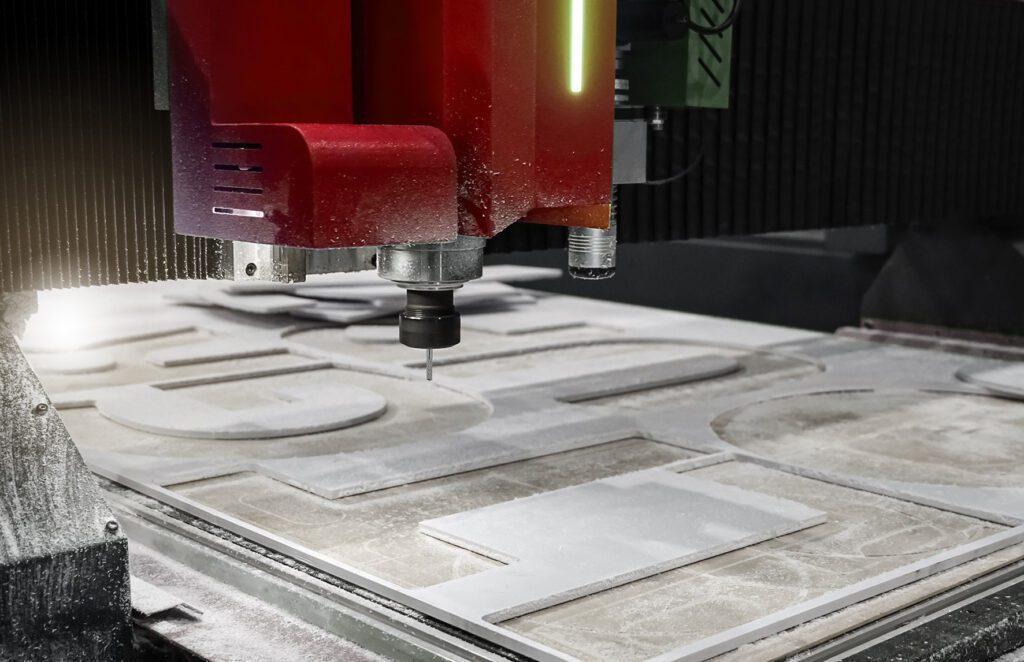

Wood is still a very important material in modern foundry pattern making. It is relatively easy to work with and readily available, and wooden moulds are suitable for making repeated impressions. Depending on the form, degree of detail and the production goal, many different tools are used in the individual processing steps to produce a casting mould. Once the raw material has been selected and cut to size, it is often machined using CNC milling machines and burrs with a special cutting geometry for wood-based materials that are specifically suited for this work.

These include the LUKAS rasp burrs from the “Wood” series made of fine-grained tungsten carbide. Their toothing ensures aggressive, fast material removal and smooth operation.

The LUKAS Wood burrs are available in various shapes and are ideal for modelling large surfaces or intricate contours. They are also perfect for tasks such as chamfering or deburring work. Thanks to their long tool life, they retain their shape even when working on hard woods. They reduce processing times and help users work quickly, while maintaining high precision and surface quality.

In addition to the highly efficient Wood burrs, LUKAS-ERZETT also offers its customers flexible grinding tools such as abrasive discs, flap discs, abrasive bands and mounted points for subsequent work steps such as surface finishing and polishing.

In other words, the ideal set of tools for making wooden moulds in foundries combines robust LUKAS tungsten carbide burrs such as the Wood burrs for fast material removal with even finer, flexible LUKAS grinding tools for detailed and finishing work. For cast patterns made of wood that are convincing in every respect. For efficient mould production and precise work results after casting.

The LUKAS Wood burrs: dimensional accuracy, precision and perfect surfaces in foundry pattern making and for mouldmaking with wood.

In foundry pattern making, high dimensional accuracy and precision are absolutely crucial. This is because any inaccuracy is transferred 1:1 to the subsequent casting mould and therefore also to the finished casting. Perfect dimensional accuracy is a must, especially for patterns for precise machine components or functional castings such as gearbox housings or engine and axle parts. Achieving this quickly and efficiently requires precise milling tools that can be guided accurately and work reliably in all situations.

This is where the Wood tungsten carbide rasp burrs from LUKAS-ERZETT, which are available in various shapes, really come into their own.

The special toothing prevents the burrs from getting caught in the material and allows for controlled, vibration-free guidance – even when working freehand. The inset chip breakers reduce the arising forces, even at fast feed and high removal rates, and allow for highly even cuts. This keeps dimensional deviations to a minimum, even with larger shapes or homogeneous material compositions. In addition, the high-quality, precision-fit steel shaft of the LUKAS Wood burrs ensures that the milling tool rotates without any play on the power tool. This allows users to produce even complex geometries, radii and transitions precisely.

The result: foundry patterns with clear edges, clean transitions and reproducible tolerances – a decisive benefit for achieving high-quality series production in foundry pattern making and in the manufacture of precise, dimensionally accurate casting moulds and cast elements.

For quality and efficiency in foundry pattern making – the Wood burr series from LUKAS-ERZETT.

Short machining times, less reworking, fewer rejects – that means quality and efficiency in foundry pattern making. To achieve this always requires maximum precision. That is because only exact foundry patterns guarantee perfect moulds and casting results.

Milling tools such as the LUKAS Wood rasp burrs made of tungsten carbide make a decisive contribution here. They enable clean, smooth contours and minimise manual reworking, reducing error rates throughout the entire process. The burrs demonstrate their quality in particular with complex geometries and tight tolerances.

The Wood burrs from LUKAS-ERZETT deliver consistently uniform results – without tearing, chatter marks or dimensional deviations.

Another benefit is their easy handling: LUKAS-ERZETT milling tools are smooth-running, easy to guide and suitable for both freehand work and CNC machines. Thanks to their extreme sharpness and the special toothing, they enable a clean and controlled removal of material. This not only saves time but also provides for exact reproducibility – an important prerequisite for fewer rejects, less reworking and therefore greater efficiency.

In short: foundries that rely on precise milling tools such as the LUKAS Wood series burrs for foundry pattern making are investing in quality and more economical processes. And that pays off.

Find out more now – and get to know the LUKAS milling tools for foundry pattern making.

Whether for single units or series production moulds, precise tools are the key to efficient foundry pattern making and successful casting processes. The Wood rasp burrs from LUKAS-ERZETT offer you exactly that in wood mouldmaking: precise dimensional accuracy, smooth running and efficient material removal.

The experts at LUKAS-ERZETT will be glad to answer your questions and give you in-depth advice about the LUKAS Wood burrs and the range for foundry pattern making, core making and mould finishing – by phone or email.