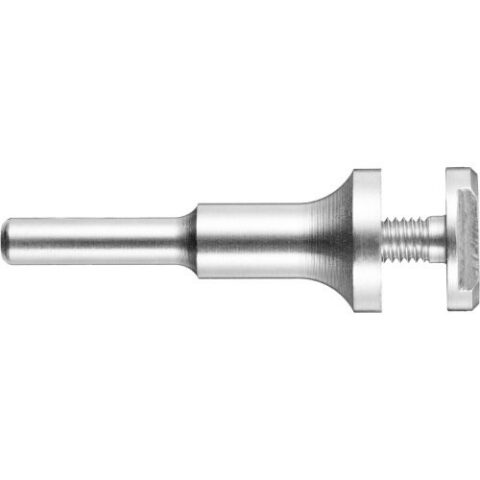

Description

The PG Easy Purple Grain is an aggressive all-rounder with an impressive service life, specially developed for heavy-duty applications. The compact grinding disc achieves impressive removal rates even with little effort, particularly on steel but also on stainless steel. The integrated glass fibre-reinforced backing pad ensures high stability and durability combined with working comfort: synchronism and aggressivity are optimised. The innovative PG tool design enables even wear without overheating, embrittlement or breakout and the deep depressed centre allows flat working. Thanks to its special tool geometry, the EASY compact grinding disc can also reach areas that are difficult to access which offers more application possibilities than a conventional tool. The PG Easy is four times faster and particularly robust compared to conventional grinding discs. The single-piece abrasive surface offers many advantages: Less wear, optimised grain adhesion, a long tool life and fewer tool changes. Another bonus is the self-sharpening effect of the ceramic grain, which enables aggressive, cool grinding with low contact pressure. Ceramic particles break off during use, making room for new ones with sharp cutting edges. As a result, this universally applicable tool achieves extremely high removal rates and a remarkable service life without much effort. Hardened surfaces, wear-resistant steels, scale and hard coatings, titanium alloys and armour welding seams are no problem and can be machined in a short time.