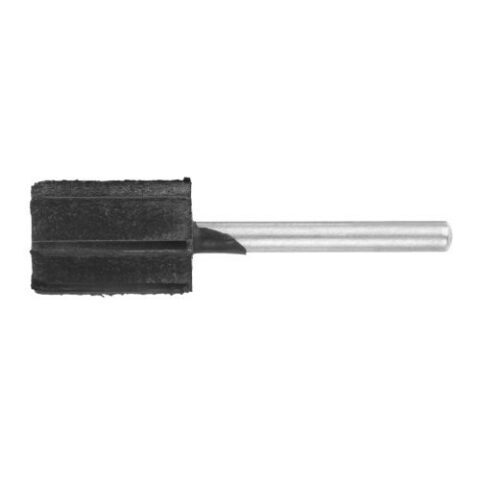

Description

The tooth geometry of the Cast burr ensures perfect surface results on cast materials. The large chip cross section provides for fast, efficient working and a high chip volume. Even with the most extreme applications, only in exceptional cases does the casting process cause cutting edge chipping, yet still with a high chip volume and an optimised cutting angle. The faceted toothing of this burr makes all this possible. The high-quality steel shank of the burr fits perfectly in the power tool. Jamming, slippage or even shaft breakage are a thing of the past. Thanks to its special chip breakers which create short chips, the tool requires little effort and the machine wear is low. The durable sharp cutting edges of the cast faceted toothing also contribute to this. The tool runs smoothly without any rattling or vibrations.