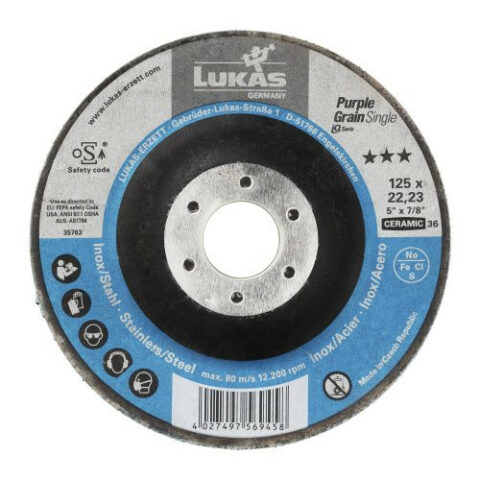

Description

Even with just a little effort, Purple Grain Single achieves stunning removal rates. The tool’s single-piece abrasive surface offers many advantages during use. This reduces disc wear and optimises grain adhesion. Fitted with a carrier made of recycled fibre and a phenol-free resin system, this tool is very light and contains significantly fewer pollutants. In addition, thanks to the fibre material the backing can wear out radially, which means that the abrasive coating in the centre of the tool is also used. The innovative design provides for even wear without overheating, embrittling or grain shredding. The deep offset zone lets you work at a flat angle. Thanks to its special tool geometry, the Purple Grain Single can also reach inaccessible areas, which offers more application possibilities than a conventional tool. This makes it ideal for machining weld seams, chamfering and removing large quantities of material. Thanks to the self-sharpening effect of the innovative ceramic abrasive grain, the Purple Grain Single always stays perfectly sharp. During use, ceramic particles break off and make space for new ones with sharp cutting edges. That is what allows this highly versatile tool to achieve very high stock removal with little force required, consistently over the tool service life and with impressive durability. Tool replacement is significantly reduced – lowering tool costs. Hardened surfaces, wear-resistant steels, scale and hard coatings, titanium alloys and reinforced weld seams are no problems and can be machined quickly. Thanks to its 22.23 mm bore the Purple Grain Single can be used with any commercially available angle grinder. It is energy-optimised so that it can also be used on the most powerful angle grinders. Regular testing ensures a high degree of reliability.