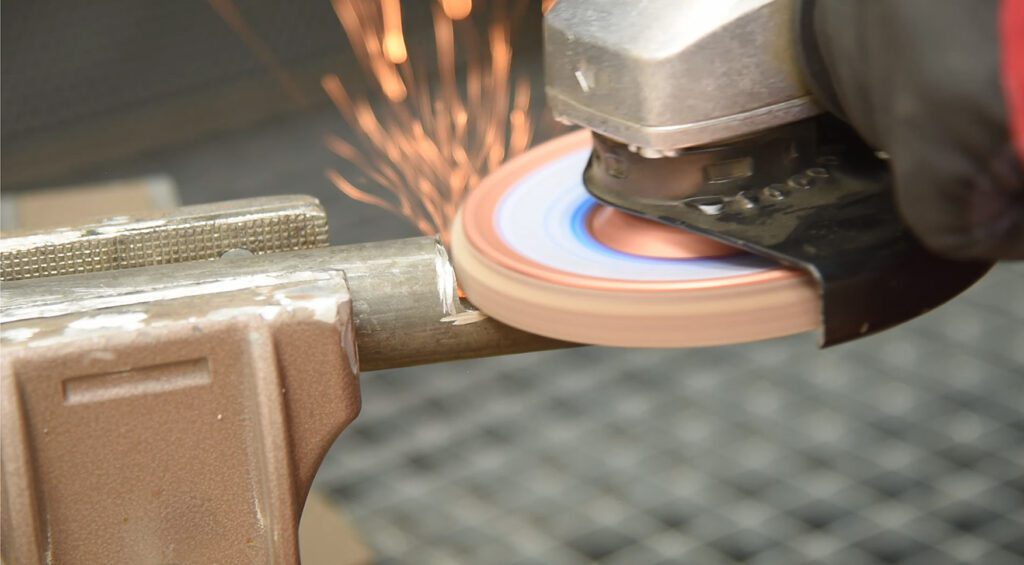

Get more out of your tools instead of constantly changing them – or why the SLTT mounted flap discs from LUKAS-ERZETT more than pay for themselves.

Anyone who only looks at the purchase price when procuring grinding tools is definitely making savings in the wrong place, and LUKAS-ERZETT’s Turbo (SLTT) flap wheels provide the proof. After using these mounted flap discs for the first time, their advantages immediately become clear to everyone: thanks to their high removal rates, long tool life, optimised working comfort, reduced machine downtimes and greater productivity, SLTT mounted flap discs from LUKAS-ERZETT contribute to tangibly lower overall costs. Whether for steel work in shipbuilding or on bridges, or in the construction of tankers, truck trailers and vehicle parts – it is obvious that choosing the right high-quality grinding tools from LUKAS-ERZETT has a significant and positive impact on the cost-benefit balance.

The LUKAS SLTT mounted flap discs in figures: a cost-benefit comparison1) that quite simply pays off.

At first glance, LUKAS SLTT mounted flap discs often appear more expensive than conventional roughing or flap discs on account of their unit price. But if you do the maths you will quickly realise:

that the actual grinding costs per kilogram of removed material are significantly lower with the Turbo flap wheels from LUKAS-ERZETT than with rough grinding discs and standard flap discs – simply because more can be achieved in less time with LUKAS-SLTT mounted flap discs.

Standard rough grinding disc

Price: approx. €1.50 – removed material: 1.5 kg – machining time: 44 minutes

➔ grinding costs2) per kilogram removed material: €24.50

Standard flap disc

Price: approx. €2.00 – removed material: 0.9 kg – machining time: 16.8 minutes

➔ grinding costs2) per kilogram removed material: €17.37

LUKAS SLTT mounted flap discs

Price: approx. €5.00 – removed material: 2.4 kg – machining time: 34 minutes

➔ grinding costs2) per kilogram removed material: just €12.67

In short: LUKAS SLTT mounted flap discs not only offer far better performance, but above all are more economical. Anyone who takes a wider view of the grinding costs – i.e. by also taking into account the working time required with the respective tool – will realise that the more that is ground with LUKAS SLTT mounted flap discs, the higher the savings.

1) Please note that the example shown here is based on tests performed under certain conditions. The stated price and performance data are exemplary calculation values to illustrate possible potential savings. Actual prices and material removal rates may differ. Please also note that all prices are for illustrative purposes only and do not constitute a binding offer.

2) At wage costs of €25/h

SLTT mounted flap discs from LUKAS-ERZETT: longer tool life – for fewer tool changes and reduced costs.

Frequent tool changes cost not only material, but also valuable time. This is where the Turbo (SLTT) flap wheels from LUKAS-ERZETT come into their own – with a significantly longer tool life compared to conventional rough grinding discs or standard flap discs. The secret lies, among other things, in the design of the SLTT mounted flap disc: the flat position of the optimally bonded sickle-shaped flaps reduces wear. A particularly large concentration of abrasive grains on the outer perimeter results in an exceptionally high removal rate per minute. And: when the top flaps wear down, the fresh abrasive coating of the flaps underneath is exposed.

This means that the SLTT mounted flap discs stay “sharp” for longer – and can work over a significantly larger area with a consistently high performance. In addition to their high grinding performance, the LUKAS SLTT mounted flap discs also have a particularly stable and robust steel backing pad, which ensures maximum reliability without the risk of breakage.

This reduces not only the number of grinding discs used, but also the number of tool changes. And that pays off, because every time work is interrupted to change the tool, it leads to downtimes, set-up effort and ultimately costs. These interruptions can be reduced to a minimum with the LUKAS SLTT mounted flap discs, making work processes smoother and more efficient – and therefore more economical.

Additionally, a longer tool life also means lower warehousing requirements, lower procurement costs and simpler logistics – because where fewer discs are used, fewer need to be kept in stock. In companies with large quantities and a lot of grinding work, this pays off in the short and long term, because it saves valuable working time, and consequently more money than a supposedly higher purchase price. A look at the cost-benefit comparison will quickly reveal that investing in SLTT mounted flap discs from LUKAS-ERZETT really pays off. For every application, every workpiece and every grinding action.

A higher volume of removed material also reduces costs. Whether in the workshop, on assembly lines or in series production, the faster and more reliably a grinding tool works, the more cost-effective the entire process. The Turbo (SLTT) flap wheels from LUKAS-ERZETT ensure, for example, an above-average removal rate per minute thanks to their sickle-shaped flaps, optimum grain distribution and the high concentration of abrasive grain in the outer perimeter – and at the same time with less physical effort.

This is felt directly as soon as the SLTT mounted flap disc makes contact with the workpiece: it gets to work immediately, removes material quickly and leaves an even surface. Instead of several passes as are necessary with traditional flap discs or rough grinding discs, a single, cleanly guided grinding process is often sufficient. This saves time – and significantly increases productivity. At the same time, employees noticeably benefit from the reduced effort and vibrations and the smooth running behaviour.

The result: more ergonomic usage, less fatigue and greater reliability – especially for longer or more challenging grinding work.

The deployed machines benefit as well: if less pressure is required, this reduces wear on the spindle, bearings and motor. And the faster the grinding, the shorter the device running times. This saves potential repair or servicing costs as well as expensive energy.

Manufacturers who want to speed up their production processes, and at the same time reduce tool and machine costs, should not just look at the price of the grinding tool. What really counts are reduced overall costs, and the SLTT mounted flap discs from LUKAS-ERZETT offer ideal conditions to achieve this reduction.

SLTT mounted flap discs from LUKAS-ERZETT: even surfaces – less reworking, better quality.

It is not only the high removal rate and long tool life of LUKAS SLTT mounted flap discs that significantly contribute to low overall costs – the surface quality is also crucial. Every additional grinding pass and time-consuming reworking job costs time and money and leads to frayed nerves. LUKAS-ERZETT’s Turbo (SLTT) flap wheels make another decisive difference here – with quality from the first to the last second.

The gradual exposure of new abrasive grains in the working area of the flaps ensures that the disc remains sharp and efficient throughout its tool life. Where conventional flap discs or rough grinding discs deteriorate, the SLTT mounted flap discs from LUKAS-ERZETT ensure a consistent surface quality – with shorter cycle times and less tool wear. The combination of precise grain, optimum pressure response and smooth running enables clean working – for chamfering, deburring and rough grinding work, as well as for machining weld seams. Alongside their high performance, the Turbo (SLTT) flap wheels also stand out due to their stable design. The robust steel backing plate offers maximum reliability (no breakages) and is therefore also suitable for use with robot systems. The good heat dissipation also ensures cool grinding and practically eliminates the need for reworking. A high-quality resin system prevents this tool from rupturing at high speeds or working temperatures.

In other words: using LUKAS-SLTT mounted flap discs always pays off. Because they simply contribute to lower costs, and make work easier for everyone involved, during grinding and in controlling.

For higher performance and lower costs: the SLTT mounted flap discs from LUKAS-ERZETT.

Using LUKAS Turbo (SLTT) flap wheels pays off wherever performance, quality and efficiency are required. High removal rates, less time spent, longer tool life, better ergonomics and a consistently high surface quality – all these factors contribute to achieving greater efficiency and a tangible reduction in the pressure on the budget and on personnel.

Please contact LUKAS-ERZETT staff by phone or email with your questions and for detailed advice about how LUKAS-SLTT mounted flap discs can help reduce costs in your company.