LUKAS-ERZETT News

News, product presentations and trends

Apprenticeships at the market leader LUKAS-ERZETT – get started on a successful future

Apprenticeships at the market leader LUKAS-ERZETT – get started on a successful future Whether it’s milling or drilling, the professionals depend on quality tools that last. That’s why they source their tools from LUKAS-ERZETT GmbH & Co. KG – become…

Milling, grinding and polishing tools for all vehicle parts – LUKAS-ERZETT with innovation and precision for the automotive industry

Milling, grinding and polishing tools for all vehicle parts – LUKAS-ERZETT with innovation and precision for the automotive industry The automotive industry faces constant challenges, from optimising production processes to ensuring the highest levels of quality and safety. In this…

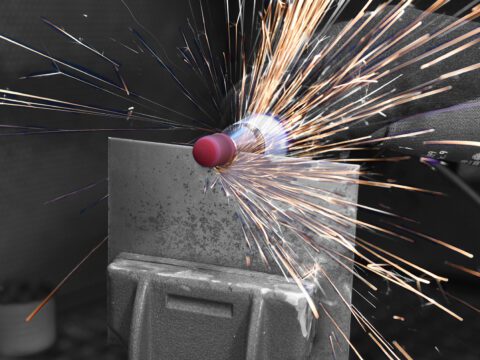

Abrasive caps: Leading-edge quality for many different applications

Exceptional quality and performance capability are the hallmarks of LUKAS abrasive caps. Thanks to state-of-the-art manufacturing technologies and high-quality materials, the abrasive caps achieve perfect results where material removal rates, surface quality and tool life are concerned.

LUKAS tools with self-sharpening effect save time in the workflow and money in use

LUKAS-ERZETT GmbH & Co. KG, as one of the technological leaders in the market for high-performance and groundbreaking milling, grinding, polishing and cutting tool solutions, stands for pioneering innovations in the tool industry. Based in the greater Cologne area, this traditional German company always focuses on customer requirements and the latest developments in a broad range of industries worldwide. One outstanding example of LUKAS quality is the ceramic grain with self-sharpening effect.

An innovative company with a history: LUKAS-ERZETT from greater Cologne area

A company’s history often reflects its values, visions and developments. At LUKAS-ERZETT, these elements are closely intertwined and shape the company’s identity as an employer and global player.

Maximising cost benefits: HypridPerfection

With the HybridPerfection Ceramic4x mounted flap disc you can remove up to 8 kilograms of steel with just one disc – a genuine powerhouse. But the real advantage lies not only in the high material removal rate, but above all in the cost-benefit ratio.

The U-Edge Pro fillet weld grinding disc: a new level of precision in weld seam machining

Weld seam machining is one of the most demanding tasks in metal processing. LUKAS-ERZETT is proud to present the U-Edge Pro fillet weld grinding disc – one of the top innovations of the year that promises to improve this process and achieve more precise results. This groundbreaking innovation offers a variety of applications for shipyards and the steel industry, as well as container construction, chemicals and the automotive sector.

Efficient tool for mould making: LUKAS-ERZETT sets standards

Efficient tool for mould making: LUKAS-ERZETT sets standards Mould making, an important area in tool and machine engineering, requires precise instruments to create complex structures and exact contours. Choosing the right tools is a decisive factor in order to be…

Highlights at the INTERNATIONAL HARDWARE TRADE FAIR – LUKAS-ERZETT with LIVE demonstrations at the booth

Highlights at the INTERNATIONAL HARDWARE TRADE FAIR – LUKAS-ERZETT with LIVE demonstrations at the booth From Sunday, 3 March, to Wednesday, 6 March 2024, the team from LUKAS-ERZETT GmbH & Co. KG is looking forward to welcoming customers and partners…

Energy transition with LUKAS tools: Precision machining for wind turbines

The rapid developments in the field of renewable energies have propelled the energy transition into new spheres. Wind turbines, which generate clean and sustainable energy, play a key role in this process. However, behind this imposing source of energy lies a complex technology that requires precise machining.